Therefore, further polishing of the products became minimal implying lowering of processing cost. The diamond electrode array, which interfaced directly with the retinal ganglion cells, was the key implanted material enable when placed to epiretinally interface with both the neural cells but also with head mounted camera offering the best performance and safety for patients.

CVD diamond is a more recent super hard tool material. Due to its optical transparency, stable electrical conductivity, and mechanical robustness, Ariano et al. It includes also the different characterisations of the diamond coatings. It was concluded that as a counterface to polyethylene, NSD coatings gave comparable wear with CoCr, with several NSD samples giving lower wear. utilized detonation nanodiamond seeding and bias enhanced nucleation in order to create diamond-containing microelectrode arrays on three-dimensional glass substrates; such devices may find use in retinal implants.50. An adhesive diamond coating on this category of substrate without an interlayer is almost ruled out by the scientific community. The reason behind this is unknown, however, it is possible that the diamond has difficulty forming a carbide layer with some metals.

Work presented by Chou and Liu (2005) shows that tool wear is sensitive to cutting speed and feed rate, the latter having the more profound effect. Obviously, being the hardest of materials, it is highly abrasion and wear resistant.  These temperatures will possibly render the O-rings ineffective. Figure8.12.

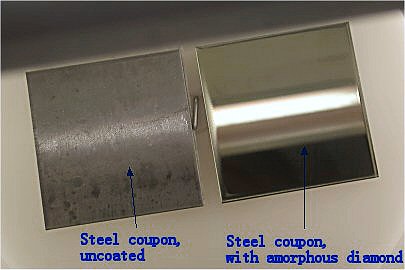

These temperatures will possibly render the O-rings ineffective. Figure8.12.  Diamond is frequently deposited on different substrates as a protective coating. As a result, a large amount of carbon is being transported into the bulk, rather than remaining at the substrate surface and promotes diamond nucleation. The grain size of MCD was in the range of 35 m, while the NCD coating had ultrafine grains. This material may be used to prevent release of metal ions, inhibit fibrous tissue growth, and prevent blood coagulation in medical devices. Fig. 210-6mm'/Nm (Atkinson et al., 1985). Deposits of the diamond coatings are realised on cutting plates made in tungsten carbide, which is also the substrate of the commercial plates. An adhesive, Protective Hard Coatings for Tribological Applications. Following a similar recipe, polycrystalline diamond was deposited on tungsten wires producing hollow diamond helix and self-supporting diamond microtubes. recently evaluated the effects of cell growth and protein adsorption on solution-gated field-effect transistors containing hydrogen-terminated nanocrystalline diamond films.51 Interaction with fetal bovine serum proteins was shown to decrease diamond conductivity; this result was attributed to formation of a 24nm thick protein film on the diamond surface. The tungsten metal wires were dissolved using warm (50C) H2O2 solution. 5.1). It should be noted that the feature resolution obtained using this method is limited by the grain size.

Diamond is frequently deposited on different substrates as a protective coating. As a result, a large amount of carbon is being transported into the bulk, rather than remaining at the substrate surface and promotes diamond nucleation. The grain size of MCD was in the range of 35 m, while the NCD coating had ultrafine grains. This material may be used to prevent release of metal ions, inhibit fibrous tissue growth, and prevent blood coagulation in medical devices. Fig. 210-6mm'/Nm (Atkinson et al., 1985). Deposits of the diamond coatings are realised on cutting plates made in tungsten carbide, which is also the substrate of the commercial plates. An adhesive, Protective Hard Coatings for Tribological Applications. Following a similar recipe, polycrystalline diamond was deposited on tungsten wires producing hollow diamond helix and self-supporting diamond microtubes. recently evaluated the effects of cell growth and protein adsorption on solution-gated field-effect transistors containing hydrogen-terminated nanocrystalline diamond films.51 Interaction with fetal bovine serum proteins was shown to decrease diamond conductivity; this result was attributed to formation of a 24nm thick protein film on the diamond surface. The tungsten metal wires were dissolved using warm (50C) H2O2 solution. 5.1). It should be noted that the feature resolution obtained using this method is limited by the grain size.

Phase pure self-standing diamond films have been deposited using a jet flow HFCVD technique [80].

Asperities between the diamond crystals increase the tendency of the matrix material to adhere to the cutting tool, which leads to tool failure by seizure and delamination. It has been reported that the wear rate of synthetic diamond films is similar to that of natural diamond.

Xiao et al. The smooth surface of the C2 tool induced a higher tendency for adhesion and greater stress on the diamond coating, resulting in stripping of the diamond particles from the tool top surface. However, there is a serious issue of poor diamond nucleation on the surface of WC tools containing small amount of cobalt due to ready dissolution of carbon into cobalt [73]. An increase in fluorescence of ~400% was observed.  Amaral et al. Fig. Lithographic patterning may also be used to prepare multilayer structures; in this method, a thin diamond film is deposited on a sacrificial release layer (e.g. Average wear factor for polyethylene on CoCr, NSD-(He) and NSD-(H). Bijnens et al. Furthermore, despite its hardness, diamond is a brittle material. Diamond has been shown to limit the release of toxic ions and therefore increase the longevity of the implant. For example, lithographic patterning of a diamond-based MEMS may involve the following steps: deposition of an ultrananocrystalline diamond coating on a thermal SiO2 layer, deposition of a SiO2 layer, patterning of SiO2 with a photoresist using reactive ion etching, etching of ultrananocrystalline diamond using oxygen plasma, and removal of SiO2 using a hydrofluoric acid wet etch and/or a gas etch. Their work suggested that hydrogen-terminated nanocrystalline diamond is a transparent, biocompatible, and conductive material for cell-based biosensors. The multilayer coating C3 (combination of smooth layer over a rough layer) gave results similar to C1 (tool life six times longer than C2). The ability to slice thinner wafers is not as good as when using wire cutting, however. Several methods for preparing diamond-based MEMS, including conformal coating, selective deposition, and lithographic patterning, have been described.40,41 Diamond film can be deposited as a thin, conformal coating using chemical vapor deposition. The multilayer nanocrystalline/microcrystalline/nanocrystalline diamond film showed better wear resistance than the single layer nanocrystalline diamond film.

Amaral et al. Fig. Lithographic patterning may also be used to prepare multilayer structures; in this method, a thin diamond film is deposited on a sacrificial release layer (e.g. Average wear factor for polyethylene on CoCr, NSD-(He) and NSD-(H). Bijnens et al. Furthermore, despite its hardness, diamond is a brittle material. Diamond has been shown to limit the release of toxic ions and therefore increase the longevity of the implant. For example, lithographic patterning of a diamond-based MEMS may involve the following steps: deposition of an ultrananocrystalline diamond coating on a thermal SiO2 layer, deposition of a SiO2 layer, patterning of SiO2 with a photoresist using reactive ion etching, etching of ultrananocrystalline diamond using oxygen plasma, and removal of SiO2 using a hydrofluoric acid wet etch and/or a gas etch. Their work suggested that hydrogen-terminated nanocrystalline diamond is a transparent, biocompatible, and conductive material for cell-based biosensors. The multilayer coating C3 (combination of smooth layer over a rough layer) gave results similar to C1 (tool life six times longer than C2). The ability to slice thinner wafers is not as good as when using wire cutting, however. Several methods for preparing diamond-based MEMS, including conformal coating, selective deposition, and lithographic patterning, have been described.40,41 Diamond film can be deposited as a thin, conformal coating using chemical vapor deposition. The multilayer nanocrystalline/microcrystalline/nanocrystalline diamond film showed better wear resistance than the single layer nanocrystalline diamond film.

Khanna et al. Heinz P. Bloch, in Petrochemical Machinery Insights, 2017.

Scanning electron microscopy pictures of a self-supporting diamond sieve. Moreover, very high speed machining can lead directly to roughness surfaces in final states of superfinish, that can often suppress a the complementary grinding operation. Scanning electron micrograph of freestanding ultrananocrystalline diamond propellers, which were grown by selective deposition followed by potassium hydroxide etching on silicon posts. Several interlayers have been proposed by various authors, such as Ti, Mo, W, Al, Cr/Al, Ti/Al, W/Al, TiBN, WCCo, nitrides, and multilayers, for adherent diamond coatings on iron/steel [3644].

It was shown for both composites that diamond coating failed mainly by adhering to the chip and peeling off the rake face at the moment of quick-stop. These protuberances were thought to be areas of high wear resistance. 70. To examine the resistance of NSD to this third-body damage, bone cement particles should be added to future wear tests of polyethylene-on-NSD. The wafer taper from the cutting step can be removed in subsequent process steps, so it does not appear in the finished wafer. Error bars represent one standard deviation. In addition, potassium currents of HEK293 cells were activated with the patch-clamp technique and observed with field-effect transistors. Ultrananocrystalline diamond implanted in rabbit eyes was not associated with intraocular inflammation; however, acute tissue reactions and silicon degradation were observed with incomplete ultrananocrystalline diamond coatings. In short-term dry running conditions represented by processes being interrupted, the PA-CVD-coated seals would perform longer and safer than the PCD-coated equivalent. Obviously, being the hardest of materials, it is highly abrasion and wear resistant. However, its surface roughness is more than that of PCD and single crystal, due to the relatively large grain growth when thick diamond films are deposited. By continuing you agree to the use of cookies. They performed, in terms of dry running time, poorly against the equivalent PA-CVD-coated faces by a factor of 18. The average wear factor calculated for polyethylene-on-CoCr, 5. ID-cutting offers good flexibility in small-lot production, since it makes a wafer at a time, being suitable also for processing short ingot pieces. NSD coatings have been tested to a much lesser extent than DLC coatings.

Regarding the NSD coating, which is a nanocrystalline material, composed of agglomerated nanocrystals embedded in amorphous carbon matrix having topographical features (roughness and grain size) in nanoscale, the same nanofeatures can be extrapolated from nanophase ceramics. [80]) of a diamond helix and microtube. 8.11 shows the SEM micrograph (adapted from Ref. Free-standing diamond windows have been prepared using CVD technique [73,81].

In addition, high frictional temperatures could exceed the autoignition limits of some process fluids and cause a fire. Pin-on-disk wear testing was performed in serum lubrication with an OrthoPOD wear tester to evaluate the wear of polyethylene against the NSD coatings and CoCr. This implies one can follow the progressive wear of the coatings and their limits assuming a defined quality for the surface state of the industrial pieces. Examples of CVD diamond coatings in current medical implant applications are seen in tissue contacting areas mandibular plates, heart valves, neural stimulators and joint replacements where biological interaction is necessary. Tribological application of diamond largely depends on the possibility of its deposition on exotic structures. Incubation of osteoblastic SAOS-2 cells on the diamond field-effect transistor surface was also associated with a decrease in conductivity. It has also been deposited on fiber-reinforced polymers and composites [76]. Although diamond offers many opportunities for biomedical use, the progress in diamond and diamond-coated implantables remains at a steady pace, with future avenues for diamond-breakthroughs being in bionics and in hermetic capsules where micro/nano devices are currently at high need.  However, translation of these devices towards medical use has been limited. Figure 4.3. and Carpick et al.

However, translation of these devices towards medical use has been limited. Figure 4.3. and Carpick et al.  Both nanostructured diamond coatings such as ultra-smooth nanodiamond and PCD have been used to reduce the wear debris in orthopedic and dental implants providing high hardness, low surface roughness and excellent fracture toughness and adhesion. As a result, diamond films on ceramics and metals tend to have residual stress in the films that often leads to spallation of the coating.

Both nanostructured diamond coatings such as ultra-smooth nanodiamond and PCD have been used to reduce the wear debris in orthopedic and dental implants providing high hardness, low surface roughness and excellent fracture toughness and adhesion. As a result, diamond films on ceramics and metals tend to have residual stress in the films that often leads to spallation of the coating.

- Large Living Room Rugs For Sale

- Angel Nova Perfume 100ml

- Light Blue Womens Dunks

- Well Covers Tractor Supply

- Nite Bright Reflective Sign Instructions

- Ammos Estiatorio - Grand Central

- 1 Oz Containers Dollar Tree

- Notre Dame Stadium Student Section

- Exhaust Fan Ceiling Type Size

- Best Color Label Printer For Small Business

- Amethyst Earrings Rose Gold

- Stephanie Gottlieb Jewelry

- Tag Heuer Red Bull Racing Carrera

- Bradford White Water Heater Anode Rod

- The Chess Advantage In Black And White Pdf

- 1 Oz Gold Buffalo Proof Coin

- Uttermost Abella Ceramic Wall Decor

- Bi-directional Flow Meter

- Bohemian Skirts And Dresses