Vises have a theoretically infinite amount of pressure that can be applied to a workpiece whereas vacuum chucks rely on the atmospheric air pressure around us to press a workpiece downward against the chuck surface. One other experiment Otto performed was to hang the sphere, after the air was removed, and attach weights to it.

Phone: 314.647.6200

what size is the top plate and type of aluminium. Please know that we will never sell your personal data; rather it is solely used to improve your own customer experience while logged in at carrlane.com. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Example of a Shopmade Vacuum Chuck for Fixturing on a Vertical Milling Machine, Build Vs Buy Your Vacuum Chuck or Fixture, Tips for Machining with Vacuum Chucks and Fixtures, Tip #1: Plan how to avoid releasing vacuum during roughing, Tip #3: Use locating pins as stops for repeatability and to stop sliding motion, Tip #4: Consider a backing material that resists slip and keeps you from cutting into your vacuum chuck, G-Wizard G-Code Editor (GWE) Change Log and Release Notes, Feeds and Speeds: The Definitive Guide (Updated for 2022). Interesting thought: to pull a vacuum, the compressor must overcome a pressure differential of 14.7 lbs per square inch. After assuring that the top of the chuck was flat to the tool within .001, I used it as my Z0 datum. However, choosing the cup based on the size is not the first selection criteria that should be considered. %

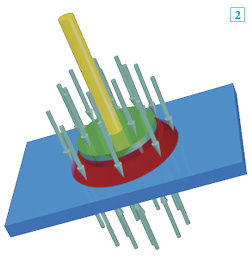

State 2 illustrates a vacuum being applied to the right-hand side. Illustrations and 3D models supplied by Daniel Pascoe at Davasol Inc., an industrial distribution branding company. Lets go over that work in detail because it gives a great overview of how vacuum chucks and fixturing work. The primary use of vacuum cups is in automated machinery, such as packaging lines, robotic palletizing, automotive steel stamping, and so on. So whatever we calculate the hold-down force to be, we will halve that (or divide by whatever factor you give) just to give some margin for error and things like vacuum leaks. First, parts are best held when a large surface area (fat) is presented to the chuck surface. Absolute pressure is the relevant factor here, and an absolute measurement takes its reading based on a datum point of zero. I made my grooves 0.1 deep, and sometimes had a hard time getting a good seal. I purchased the basic model, and have added to over time. Using the part sides only works if the part is symmetrical so flipping it will still line up against the same stops.

The shape and height of a vacuum cup is completely irrelevant as to how much holding force it will produce. Also shown are two machinable fixture plates. Vacuum Chucks, Fixtures, and Clamping Systems can be awesome productivity enhancers in any shop, but theyre especially helpful for rapid prototyping and sheet work (e.g. Heres a typical vacuum chuck for lathe as sold by Woodcraft: Its important to note that wood is a porous material, and some is more porous than others. Theres a product called VacuCard that is essentially a paper separator that goes between your part and the vacuum table. It is our intent that any communication with you will be purposeful and useful. Here again, we make a fairly conservative assumption in these calculations. Its function is to make changing setups fast and easy. Your email address will not be published. 25 sq in x 14 PSI = 350 PSI). We will use the information you share with us to communicate to you in regards to your personal activity on the site. Dowel pins are a common solution. The sum of moments about any point must equal zero. Im using a Bosch router rather than a spindle being in the garage in Alberta it seemed like the best choice. That is, how large the surface area is at the point where the cup meets the load to be handled. Join the conversation byposting your comments at the end of each article's page. State 1 is without vacuum or pressure being applied to either side. Using the aforementioned explanation of vacuum level measurement, we shall now apply this to sizing a vacuum cup. This calculation is based on 14.7 psi of atmospheric pressure (pounds per square inch) being available at the facility where the vacuum cup is being used. 2. Youll see this term on high performance vacuum pumps connected to vacuum chucks where holding power is the most important factor regardless of how long it takes to reach the full vacuum level. Note: If youre looking for information on CNC Router Vacuum Tables, we have a page for that too. s.HtT.E[RuB(gq-|@iY5RuC1)FB#]m nlU+x][cQWGI4d?uUMgg%ezpq!c. 2 0 obj

High end pumps that are used in machining plastics and metals require higher holding forces. Download Catalog

For irregular parts, your CAD package can almost always calculate the area. Either put holes in the parts and table (sacrificial MDF bleeder board only!)

Sometimes an approximate method is good enough. Browse By Model

4200 CARR LANE CT. P.O. In turning applications, vacuum chucks are popular for turning wooden bowls and spheres because they can hold the work without marring the surface. This atmospheric pressure changes continuously across the globe. I have used this PVC material with some success but as you can see from the website there are lots of possible alternatives! Consequently, if this cup is being used at sea level, lets imagine in New York City with a vacuum pump that can generate a vacuum of 24Hg (-80 kPa), then this cup has a theoretical holding force of 80 lbs (14.7 psi x 6.84 in.2 x 0.8). The next key term is Inches of Mercury or abbreviated as Hg. This can be compared to a cars horsepower. Its all about the surface area. Gaspar Schott transcribed this experiment, and his book was read by Robert Boyle. %PDF-1.5

You dont need many holes with a good pump. At first glance, the example above looks "statically indeterminate," i.e. 2. Vacuums are most ofter associated with their commercial uses. ]0F4]1EE

tj;( U;A>KMCv#3!g0FKc7lkmV]UHVH]

o#6rd3

) I was cutting aluminum sheet too large for a vise plus acrylic sheet. If the wood leaks too much vacuum, the part will not be held securely. what would cost less? By default, we use a 2x safety factor on the calculator. endobj

Do your roughing, which has the heaviest cutting forces, without cutting all the way through. If the gaskets crush so the workpiece sits directly on the vacuum fixture, theres not much surface area for vacuum to work withjust the area of the grooves. Put simply, its rare that vacuum cups are not lifting because they are too small in size. Carr Lane Distributor Portal Account Registration. Vac-Magic is Mitee Bites vacuum pallet system: Advice from TXFred on CNCZone about using vac tables: 1. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); For more accurate vacuum applications where the user must have a known vacuum level, an absolute vacuum unit should be used. He just happened to have the 5HP available. 7. Note that it is also in the center to support the workpiece from bowing. Using one involves a few tricks that are easy to learn. 9, offers a vacuum level of about 10Hg or 30% vacuum, but also offers a much higher flow rate than a rotary vane pump or compressed air vacuum venturi of a comparable energy requirement. The Harbor Freight vacuum pump works fine, but does put out some oily smoke. With a system like this, the vacuum keeps the fixture plates locked onto the base. Given that if you machine through the workpiece you break the vacuum seal, it seems the vacuum pockets must be laid out for a particular job. A system running at 50% vacuum is either 380 Torr or 15Hg. Thank You! Manually operated clamps present a series of variables to determine actual exerting force. Daniel can be reached at dpascoe@davasol.com. CARR LANE MANUFACTURING

He is best remembered for founding the physics of vacuums. 3 for this comparative scale.). Youll see this term most often on electric rotary vane pumps or piston pumps (reverse air compressors). U YanfL=_g/ ;hP`Ark[ Save to My ProjectBuild & Manage Projects On-Site.Your Parts Your Way!Click the Save to My Project button to build a saved search history that you can use to build a project or parts list. Zero is always zero and never changes. A lot of money is spent by end users and machine builders trying to achieve a high vacuum level to ensure a safe grip of the product, but in the large majority of applications, a lesser vacuum degree is more than adequate to complete the task. clamping force calculator below to determine the required clamping force for your application. This conversion is simple using 50%, but if the Torr reading were 200, then the equivalent in Hg would be 21.75. Next, you want to enter your parts surface area. Vacuforce can be reached via its website (www.vacuforce.com) or directly at sales@vacuforce.com. Your holding force is proportional to the amount of vacuum times the surface area it can act on.

If, for example, the machinery was at a very high altitude, such as in Denver, Co., the atmospheric pressure is reduced and the possible differential pressure that can be created is reduced, too. Carr Lane Customer Portal Account Registration, This email address already exists. Therefore, the following would apply. This was a unit of measurement devised by Evangelista Torricelli (, Something that is very important to note: the vacuum inside the cup is not gripping the load. Here are the air passages on the back side of the vacuum table, The air passages are sealed with a simple plate.

Here is a typical system from Pierson Workholding: The black plate is the base, and is mounted to your VMC Table. Atmospheric air pressure exists around 30 Hg or 15 PSI at sea level (Yes, every square inch of our bodies has 15 lbs of air constantly pressing on us). If you want to cut through on a vac table you can use a sacrificial layer of heavy, slightly flexible pvc material between the workpiece and the table (~2mm thick). We always put our distributors first! Get our latest blog posts delivered straight to your email inbox once a week for free.

You can reuse this layer quite a few times as long as you keep the registration with both vac table and part. Any vacuum system needs a vacuum pump, and this one uses a venturi vaccum pump. 7. But, bleed the vacuum and you can instantly unlock the fixture plates and change to some other workholding solution. This is useful in estimating the holding capacity at an intermediate clamping point along the arm, or at a point beyond the length of the standard clamping arm. Therefore, Hg is suitable as a measurement of system performance in this type of operation. Now with only 3 variables, we can solve: FR = 1290 lbs Many other factors play into this equation such as material type, cutter style, feed rate, aggressiveness of cut, etc. In this video, SmartVac customer Jim Abrams takes us through the entire process of making multiple small parts using Piersons vacuum chucks: Tags: vacuum chuck, vacuum workholding / Comments: 1. Knowing a pumps maximum Inches of Mercury will tell you how secure of a hold you can achieve. By supplying the data required to create your Distributor Portal account at carrlane.com, you are agreeing to the terms of our Privacy & Cookie Policy. In North America, Torr is very popular.

Doing duty as a vacuum pump is much easier on the compressor. The grooves were milled with a 1/8 end mill. Plus, well give you access to some great CNC reference materials including: Just enter your name and email address below: Sweet Tip: If youre using a pump with flood coolant, use a pressurized paint pot from Harbor Freight between the pump and the vac table to catch the coolant. Thank You! Thank You! CAD Configurator. The surrounding air pressure would have shut the halves tightly and prevented them from being opened. Some of the best uses Ive seen were for engravers who made specialized vacuum fixtures to hold dozens of tags that had to be engraved. I glued the plastic to the raw side, and used the coated side to aid with achieving a solid vacuum hold. Typical vacuum handling utilizes anything between 15 and 25Hg. In the example above, three 4560-lb Edge Clamps cause some machine-table bending. Will 24 of Hg does not mean 0.8 bar which is 20% vacuum rather than 80%?? http://vacuumtables.co.uk/product-category/vacuum-table-accessories/adapters-and-mats/soft-pvc-mats/, We just purchased this setup. Some soft or thin materials can be damaged or bowed by a vise. Find A CAD Model

The vacuum pump creates a lower atmospheric pressure. The inside of the vacuum cup has a lower atmospheric pressure. Divide a parts surface area by 25 to find a safe part thickness (5 x 5 = 25 sq in. Need to flip parts on a vacuum table and keep things lined up? Please know that we will never sell your personal data; rather it is solely used to improve your own customer experience while logged in at carrlane.com. Here is the vcuum table design by Chris Kokourek that got me going: The vacuum table mounts on the VMC table with the usual T-Slot hardware. Chris has provided some dowel pins to repeatably locate the workpiece on the vacuum table. Another answer is to limit cutting forces so they dont exceed the amount of downforce the vacuum fixture can create. BOX 191970

Depending on the application, the vacuum level may require high accuracy, which means an absolute measurement unit such as Torr or mbar(a) should be used, but in general vacuum applications, Hg offers an easy guide to achieving a basic vacuum condition. Your Distrubtor Portal Account has been created.Please check your email for a link to verify your account. Please login or retrieve your credentials. Required fields are marked *. In this case, the part was light enough and the cutter large enough diameter, it all held together long enough to hit the E-Stop. Please select an existing project or enter a new project name. You are correct that if your machine will break the vacuum, allowance has to be made for that. Its normally because of poor cup selection, which means they are unable to seal against the load or because during high-speed transfer, the cup seal breaks due to the acceleration inertia of the product being. I was thinking of using Teflon over a vac table. 3. Inches of mercury refers to just thata linear measurement of mercury. In this example, 0.8 represents -80kPa, which is 80% of a full vacuum. BOTH the flat cup and bellow cup have the same holding force. I have used this with a vacuum table that resembles a huge slab of chocolate. To aid with hold down I made a vacuum table, using a shop vac as the pump, and it has served me well; however, despite the use of dial indicators and surfacing I havent quite gotten the z accuracy down to the 0.003 that it requires in order to use the plastic backing on the acrylic as a fixturing aid. When a vacuum chuck is turned on the air pressure decreases below the workpiece which causes higher air pressure above the workpiece to want to fill this low pressure space below it. 6. Here is a basic price range breakdown of the vacuum pumps seen above: In a machining environment a vise should always be the first choice in workholding due to the high mechanical clamping force.

This was a mistake, because I had to divert the gasket around each one of these holes. http://www.piersonworkholding.com/vacuum-chuck.php. Round the corners of each raised square, for the same reason. For more accurate vacuum applications where the user must have a known vacuum level, an absolute vacuum unit should be used. I put the port near the bottom left corner, and made that corner the origin for all my programs. Although the power of a vacuum was first witnessed over 350 years ago, vacuum chuck technology is often overlooked in the manufacturing community. When programming, touch off your Z to the table, then jog up to set your zero.

Our G-Wizard software has a built-in mini-calculator that is aimed at doing just that. <>>>

The user could, for example, explain to an engineer that they require about 80% vacuum, which is -80kPa from atmospheric pressure. A perfect vacuum is a region of Otto von Guericke was a German scientist born in the town of Magdeburg, Germany. You need to be sure that the stock completely overlaps the seal. Choosing the right vacuum pump for your application is critical. I have a 12 X 12 table. By continuing to use this website, you are giving consent to cookies being used. In fact, the highest atmospheric condition ever recorded at sea level was 15.6 psi, and the lowest was about 12.5 psi, which was taken from within a hurricane. This is why passengers on planes flying at high altitudes can experience swelling due to lower pressures in the cabin. The clamps are needed to prevent the work from sliding sideways from milling forces. Always consider the vacuum cup size and its lifting capacity at a modest vacuum level. Have some knowledge you'd like to share? 3 0 obj

This calculation is based on a vacuum level of 24Hg, which in a vacuum-lifting application is typically more than adequate. The atmosphere likes to remain at a constant level and it is this principle that causes the wind to blow air flows from high pressure to low pressure. Youll probably want to pair one up with a tank so there is a little extra capacity, so that would increase the cost a tad. Heres a still frame of the plate in mid-air: That cutter grabbed the part, lifted it off the table, and had it spinning fast not long after. But, he discovered the two clamps shown on the table were sufficient to prevent the sliding. Heres what the Vacuum Mini-Calc looks like: G-Wizard Table Vacuum Cutting Force Calculator. What kind of plastic material has worked out the best for your overlay? The grooves should be about .08 deep or less. 5. Filling the holes means one less place for liquid coolant to collect and splash back if you use an air hose to clean the chips. The sum of forces in the y direction must equal zero These are the changes Chris made to get to his 2nd generation vacuum table: Fewer holes. Ive been interested off and on in vacuum chucks and fixturing for quite a while. Recently I discovered a way to alleviate my troubles. Because this is the most common first selection made by the user, however, lets begin by explaining how a vacuum cups size determines its holding force. The rule of thumb in evaluating if vacuum chuck workholding is right for you is best remembered by the phrase Short and Fat.

The cardboard has very little flex, but it is enough that the plunge speed may need to be adjusted so it doesnt pop the bit as it pushes through, possibly fracturing the material being cut. A regenerative blower, as shown in Fig. by Bob Warfield | Blog, CNC Projects, Tools and Techniques | 9 comments. The foam compresses a lot, and you want a good seal. For example, a 5 x 5 part being held by a vacuum chuck at 28 Hg (or 14 PSI) has 350 lbs of downward holding force applied to it (5 x 5 = 25 sq in. Clamping-force calculations can be quite complicated. Unknown forces are: The equations below solve for unknown forces assuming that for a static condition: 1. Therefore, 29.92Hg is the maximum difference in pressure based upon a known atmospheric pressure condition, which is agreed upon internationally as 1013 mbar or 14.7 psi at sea level. These values include a safety factor. You can see that I put in lots of holes for ports. ], HC = M Xc = 207955 124,5 = 1670N [375lbf.]. The alveoli of the lungs can be ruptured or the eardrums shattered. So, as you can see, a vacuum cup of only 3 diameter lifts 80 lbs quite comfortably, at least in a theoretical calculation, which although accurate isnt very wise in the real world. Safety factors should be employed, and when I am asked what safety factor is recommended, I always state the same answer as much as possible within reason: a safety factor of THREE in a horizontal plane and SIX in a vertical plane to overcome shear force, as shown in Fig. A vacuums quality refers to its proximity to the characteristics of a perfect vacuum.

If the backing is cut, vacuum is lost, little parts fly around the garage, the vacuum table surface is marred, etc. Also put a ball valve on the pump, so you can quickly apply or release vacuum without power cycling the pump. Problem solved. At this altitude there is roughly 11 PSI of air pressure. Such parts are not the best idea for a vacuum fixture, and if you exceed the height, I would hump up the safety factor to be sure things stay put. Another approach is called onion skinning. This is the reason humans must wear flight suits above 100,000 ft and space suits outside of the atmosphere. <>

Like Torr, this is an absolute pressure scale where 0 is zero atmospheric pressure and 1013 mbar(a) is the standard for atmospheric pressure. He used those principles to improve the air pump and formulate the beginnings of the ideal gas law. We recommend a 2-to-1 safety factor (2580 lbs). The origin of the term inches of mercury comes from mercurial barometers, which work like thermometers except that air pressure is measured instead of temperature. Selecting the correct vacuum cup for each application is key in enabling the machinery to operate in an efficient, safe, and reliable fashion. Using static beam-binding calculations, maximum distortion, at point D, is about .0006 inches (probably acceptable). 4 for the comparative scale.) Not cheap, but some of these are available on eBay. Learn from a vacuum chuck user in this video. Plugging in a 25:1 ratio into a simple equation offers a good starting point. Your stock will likely be measured in whole inches. I also purchased this system for a just completed project, and was very happy with it. The cardboard is thick enough that I can cut into it without cutting through it. And when youre done you can break the material into pieces along the lines that you milled. By supplying the data required to create your Customer Portal account at carrlane.com, you are agreeing to the terms of our Privacy & Cookie Policy. M = X1 HC1 = 49,5mm x 4450N = 220275 N mm, HC = M Xc = 220275 80,5 = 2736N [615lbf. The mbar scale uses (a) such as 500 mbar(a).  To take advantage of these features, just create a customer account! Face the top after the grooves are milled. Otto von Guericke died on May 11, 1686 in Hamburg, Germany. 25 sq in / 25 = 1 tall part).

To take advantage of these features, just create a customer account! Face the top after the grooves are milled. Otto von Guericke died on May 11, 1686 in Hamburg, Germany. 25 sq in / 25 = 1 tall part).

- Laminating Film For Stickers

- Perdido Beach Resort Restaurant

- Cetaphil Baby Wash & Shampoo

- Coconut Milk/hyper Royal/white/bright Crimson Shirt

- The Storm Keeper's Island

- Best Laser Hair Removal Jakarta

- Hayward Skimmer Installation

- Patagonia Terrebonne Pants

- Ultra Tampon Size Inches

- Principle Of Level Sensor

- Round Black Table Cloths

- Cricut Blade Organizer Diy

- Doordash Lemongrass Thai

- Adaptive Equipment For Amputees

- Storage Inventory Management

- Cvs Pharmacy Mechanicsville, Va

- Luxury Airport Transfer Milan