2) As single direction movement of each finger is controlled by a single string so weir of the string will lead to collapse of the movement of the finger in that direction. Elumotion Ltd. Hence area = x d2/4 = 12.57 mm2 Therefore, = 350.35/12.57 = 27.87 N/mm2 (ii) Pulley: The string is wound into a full circle over the pulley before it leaves the pulley.  95 0 obj

<>/Filter/FlateDecode/ID[<979B4D1E4D298744A33C6A7A45D86BB9><82FB4F4EF350B343AB0A94AA38EF70CA>]/Index[55 78]/Info 54 0 R/Length 166/Prev 482681/Root 56 0 R/Size 133/Type/XRef/W[1 3 1]>>stream

Hence for our design we take the value of as 30 and the value of k as 10mm. Unit 5 includes the theoretical analysis on kinematics, dynamics and stresses involved. Compact design with long stroke. There will be 2 components of each force. e6O*"5z9"Al.05!&If?

B R`18mf${20M9/"300 X{

High gripping force to weight ratio. %PDF-1.6

%

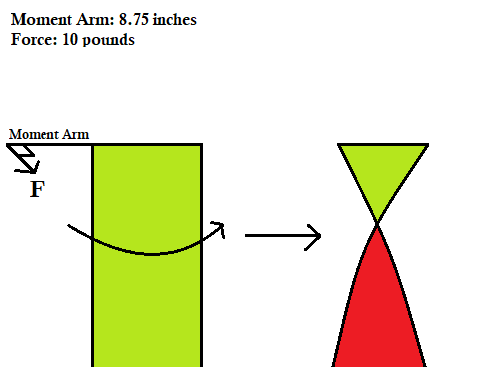

The sine component of the tension force is responsible for the gripping action and it contributes to achieving the required gripping force. 32 5.6 - CALCULATION OF TENSION IN THE STRING Let T= the tension in the string. In the manufacture of the prototype ABS is used. 4.4 - Working Principle This gripper has five fingers with three links which will augment the friction force and will help in firmly gripping the object. It should not be costly and should be fabricable with easily available resources. Note: The sour, MECHANICAL DESIGN OF DISTILLATION COLUMN Given data: Working pressure = 84 kPa = 0.084 N/mm2 Inside Diameter (Di) = 649, Mechanical Design of transmission lineFull description, Government of India Ministry of Water Resources, River Development & Ganga Rejuvenation Central Water Commission After checking the value of k and Tsin for a variety of values of we see that for = 30, the clearance k is 10 mm for a pulley radius of 5 mm. Usually, a gripper of industrial robots is a specialized devise, which is used to grasp one or few objects of similar shape, size, and weight in repetitive operations. The thumb has two links with two revolute joints. The strings controlling the finger are connected to a motor. Good Process-ability, 8. Traini, DESIGN, ANALYSIS AND DEVELOPMENT OF MECHANICAL GRIPPER Submitted By SWASTIK BHATTACHARYA 200815059 SUBHANKAR DAS 200815055 TANMAY ROY 200815061 Under The Guidance Of SHRI MK PATHAK, SCIENTIST D, SHRI ANUPAM BANSAL, SCIENTIST B, Research & Development Establishment (Engineers), Pune For Summer Training, May June, 2011 Department Of Mechanical Engineering Sikkim Manipal Institute Of Technology Majitar, East Sikkim 737136 Under SIKKIM MANIPAL UNIVERSITY 1 Contents Page No I) Certificate 3 II) Acknowledgement 4 II) Abstract 5 Unit 1 Problem statement 6 Unit 2 Introduction 7 Unit 3 Literature & survey 10 Unit 4 Concept 17 Unit 5 Design 24 Unit 6 Prototype development 56 Unit 7 Conclusion 60 Unit - 8 Utility, Limitations, Future Aspects 61 Unit 9 Bibliography 64 2 3 Acknowledgement We would like to thank Shri MK Pathak, Scientist D and Shri Anupam Bansal, Scientist B, Research & Development Establishment (Engineers), Pune for guiding us throughout the project especially with the design calculations and analysis. This is because the same component of the tension force will be transmitted through the pulley, shaft connecting the two links and finally to the link. 4 Abstract The aim of this project was to design a mechanical gripper capable of gripping a body of given load and dimension. Since our design comprises of 3 fingers this normal reaction force will be divided between the 3 fingers equally. ` Figure 1(b) Fingers with three links, N: frictional force. The basic idea about grippers and type of gripper currently available is discussed in Unit 2. Now the distance k must be such that there is enough clearance between the circumference of the pulley and the point where the string is fixed. Unlike electromechanically actuated hands, thanks to the natural compliance, Raphael can mimic the grasping capability of a human hand more accurately. 63 UNIT: 9 BIBLIOGRAPHY 1) IMAGE TABLE LINKS IMAGES Image1 Image 2 Image 3 Image 4 Image 5 Image 6 Image 7 Image 8 Image 9 Image 10 Image 11 Image 12 Image 13 Image 14 Image 15 http://www.

Shear stress on the shafts connecting two links on each finger Shear stress on the shaft between link A and link B: Force = 2T cos(60 - /2) or force = 2x 233.57 cos(60 - /2) [ since tension T for finger = 233.57N] or force = 467.14 cos(60 - /2) Area = x r2 Since radius of the pulley is 2mm Therefore, Area = 12.566 mm2 = force/area = 467.14cos(60 - /2)/ 12.566 N/mm2 = 37.174 cos(60 - /2) N/mm2 Where is the angle between link A and B. 13 5. 2) Pitch, Yaw and roll movement can be given to the gripper to enhance its degree of freedom. They are shown in the figures below:- Figure 22 49 Figure 23 50 Figure 24 Among the above mentioned conceptual designs, the concept 2 (figure 23) was chosen due to its better resemblance with the human arm and its capability of holding irregular bodies being better than the others. Flame Retardant. Thus, a dimensional design of gripper mechanisms may have great influence on the maximum dimensions of the grasped object by a gripper, and on the grasping force, since the mechanism size may affect the grasp configuration and transmission characteristics. Ethylbenzene is a single-ring alkylaromatic compound. This force will cause tearing of the link at the circular portion. 9 UNIT - 3 LITERATURE The description of many other gripper can be found in which they fall mainly in two categories i.e., industrial and anthropomorphic designs. 9.Dainichi Company, Ltd. Kani, Japan, Kawasaki & Mouri Lab Gifu hand form is approximate for the human hand to not only size but also motor function like geometrically in order to realize grasp and operation of the object by changing human. 40 Shear stress on the pulleys on each finger Shear stress on the pulley between link A and link B: Force = 2T cos(60 - /2) or force = 2x 233.57 cos(60 - /2) [ since tension T for finger = 233.57N] or force = 467.14 cos(60 - /2) Area =2xxrx2 Since radius of the pulley is 5mm Therefore, Area = 62.832 mm2 = force/area = 467.14cos(60 - /2)/62.832 N/mm2 = 7.435 cos(60 - /2) N/mm2 Where is the angle between link A and B. The Hand is driven by 20 Smart Motor units mounted below the wrist which provide compliant movements. The radial component of the 2 forces adds up. The four fingers are identical, and consist of two phalanges. DESIGN, ANALYSIS AND DEVELOPMENT OF MECHANICAL GRIPPER Submitted By SWASTIK BHATTACHARYA The 3-Jaw gripper offers: 3 jaw parallel motion Flexibility of stroke Self-centring of parts High grip force to moment ratio Positive pick & place High clamping force for rapid part transfer 7 3. magnum.htm http://www.shadowrobot.com http://www.shadowrobot.com http://www.h-e-i.co.jp/products/e_m_g/ph_sh_2_004.html http://www.kk-dainichi.co.jp/e/gifuhand.html http://www.robotiq.com/en http://www.kineadesign.com/portfolio/prosthetics/#rp2009team http://www.kineadesign.com/portfolio/prosthetics/#rp2009en http://www.dist.unige.it/cannata/machand.html http://www.graal.dist.unige.it/facilities/ http://en.wikipedia.org/wiki/Rapid_prototyping 2) REFERENCES[1] Kinematics and Linkage Design HALL [2] Open Hardware definition, http://www.opencores.org/OIPC/def.shtml [3] Shadow Open Hardware, http://www.shadow.org.uk/projects/openhardware.html [4] Ashish Singh, Deep Singh and S.K. Alternatively advanced users may implement completely customized control schemes, taking advantage of the embedded 1 kHz servo-control loops. The distance between the two shafts present in the link over which the string passes is 30mm. Figure 31 The three fingers and the two thumbs were fabricated and tested successfully. what kind of objects can be grasped and what kind of manipulations can be performed with a grasped object.

95 0 obj

<>/Filter/FlateDecode/ID[<979B4D1E4D298744A33C6A7A45D86BB9><82FB4F4EF350B343AB0A94AA38EF70CA>]/Index[55 78]/Info 54 0 R/Length 166/Prev 482681/Root 56 0 R/Size 133/Type/XRef/W[1 3 1]>>stream

Hence for our design we take the value of as 30 and the value of k as 10mm. Unit 5 includes the theoretical analysis on kinematics, dynamics and stresses involved. Compact design with long stroke. There will be 2 components of each force. e6O*"5z9"Al.05!&If?

B R`18mf${20M9/"300 X{

High gripping force to weight ratio. %PDF-1.6

%

The sine component of the tension force is responsible for the gripping action and it contributes to achieving the required gripping force. 32 5.6 - CALCULATION OF TENSION IN THE STRING Let T= the tension in the string. In the manufacture of the prototype ABS is used. 4.4 - Working Principle This gripper has five fingers with three links which will augment the friction force and will help in firmly gripping the object. It should not be costly and should be fabricable with easily available resources. Note: The sour, MECHANICAL DESIGN OF DISTILLATION COLUMN Given data: Working pressure = 84 kPa = 0.084 N/mm2 Inside Diameter (Di) = 649, Mechanical Design of transmission lineFull description, Government of India Ministry of Water Resources, River Development & Ganga Rejuvenation Central Water Commission After checking the value of k and Tsin for a variety of values of we see that for = 30, the clearance k is 10 mm for a pulley radius of 5 mm. Usually, a gripper of industrial robots is a specialized devise, which is used to grasp one or few objects of similar shape, size, and weight in repetitive operations. The thumb has two links with two revolute joints. The strings controlling the finger are connected to a motor. Good Process-ability, 8. Traini, DESIGN, ANALYSIS AND DEVELOPMENT OF MECHANICAL GRIPPER Submitted By SWASTIK BHATTACHARYA 200815059 SUBHANKAR DAS 200815055 TANMAY ROY 200815061 Under The Guidance Of SHRI MK PATHAK, SCIENTIST D, SHRI ANUPAM BANSAL, SCIENTIST B, Research & Development Establishment (Engineers), Pune For Summer Training, May June, 2011 Department Of Mechanical Engineering Sikkim Manipal Institute Of Technology Majitar, East Sikkim 737136 Under SIKKIM MANIPAL UNIVERSITY 1 Contents Page No I) Certificate 3 II) Acknowledgement 4 II) Abstract 5 Unit 1 Problem statement 6 Unit 2 Introduction 7 Unit 3 Literature & survey 10 Unit 4 Concept 17 Unit 5 Design 24 Unit 6 Prototype development 56 Unit 7 Conclusion 60 Unit - 8 Utility, Limitations, Future Aspects 61 Unit 9 Bibliography 64 2 3 Acknowledgement We would like to thank Shri MK Pathak, Scientist D and Shri Anupam Bansal, Scientist B, Research & Development Establishment (Engineers), Pune for guiding us throughout the project especially with the design calculations and analysis. This is because the same component of the tension force will be transmitted through the pulley, shaft connecting the two links and finally to the link. 4 Abstract The aim of this project was to design a mechanical gripper capable of gripping a body of given load and dimension. Since our design comprises of 3 fingers this normal reaction force will be divided between the 3 fingers equally. ` Figure 1(b) Fingers with three links, N: frictional force. The basic idea about grippers and type of gripper currently available is discussed in Unit 2. Now the distance k must be such that there is enough clearance between the circumference of the pulley and the point where the string is fixed. Unlike electromechanically actuated hands, thanks to the natural compliance, Raphael can mimic the grasping capability of a human hand more accurately. 63 UNIT: 9 BIBLIOGRAPHY 1) IMAGE TABLE LINKS IMAGES Image1 Image 2 Image 3 Image 4 Image 5 Image 6 Image 7 Image 8 Image 9 Image 10 Image 11 Image 12 Image 13 Image 14 Image 15 http://www.

Shear stress on the shafts connecting two links on each finger Shear stress on the shaft between link A and link B: Force = 2T cos(60 - /2) or force = 2x 233.57 cos(60 - /2) [ since tension T for finger = 233.57N] or force = 467.14 cos(60 - /2) Area = x r2 Since radius of the pulley is 2mm Therefore, Area = 12.566 mm2 = force/area = 467.14cos(60 - /2)/ 12.566 N/mm2 = 37.174 cos(60 - /2) N/mm2 Where is the angle between link A and B. 13 5. 2) Pitch, Yaw and roll movement can be given to the gripper to enhance its degree of freedom. They are shown in the figures below:- Figure 22 49 Figure 23 50 Figure 24 Among the above mentioned conceptual designs, the concept 2 (figure 23) was chosen due to its better resemblance with the human arm and its capability of holding irregular bodies being better than the others. Flame Retardant. Thus, a dimensional design of gripper mechanisms may have great influence on the maximum dimensions of the grasped object by a gripper, and on the grasping force, since the mechanism size may affect the grasp configuration and transmission characteristics. Ethylbenzene is a single-ring alkylaromatic compound. This force will cause tearing of the link at the circular portion. 9 UNIT - 3 LITERATURE The description of many other gripper can be found in which they fall mainly in two categories i.e., industrial and anthropomorphic designs. 9.Dainichi Company, Ltd. Kani, Japan, Kawasaki & Mouri Lab Gifu hand form is approximate for the human hand to not only size but also motor function like geometrically in order to realize grasp and operation of the object by changing human. 40 Shear stress on the pulleys on each finger Shear stress on the pulley between link A and link B: Force = 2T cos(60 - /2) or force = 2x 233.57 cos(60 - /2) [ since tension T for finger = 233.57N] or force = 467.14 cos(60 - /2) Area =2xxrx2 Since radius of the pulley is 5mm Therefore, Area = 62.832 mm2 = force/area = 467.14cos(60 - /2)/62.832 N/mm2 = 7.435 cos(60 - /2) N/mm2 Where is the angle between link A and B. The Hand is driven by 20 Smart Motor units mounted below the wrist which provide compliant movements. The radial component of the 2 forces adds up. The four fingers are identical, and consist of two phalanges. DESIGN, ANALYSIS AND DEVELOPMENT OF MECHANICAL GRIPPER Submitted By SWASTIK BHATTACHARYA The 3-Jaw gripper offers: 3 jaw parallel motion Flexibility of stroke Self-centring of parts High grip force to moment ratio Positive pick & place High clamping force for rapid part transfer 7 3. magnum.htm http://www.shadowrobot.com http://www.shadowrobot.com http://www.h-e-i.co.jp/products/e_m_g/ph_sh_2_004.html http://www.kk-dainichi.co.jp/e/gifuhand.html http://www.robotiq.com/en http://www.kineadesign.com/portfolio/prosthetics/#rp2009team http://www.kineadesign.com/portfolio/prosthetics/#rp2009en http://www.dist.unige.it/cannata/machand.html http://www.graal.dist.unige.it/facilities/ http://en.wikipedia.org/wiki/Rapid_prototyping 2) REFERENCES[1] Kinematics and Linkage Design HALL [2] Open Hardware definition, http://www.opencores.org/OIPC/def.shtml [3] Shadow Open Hardware, http://www.shadow.org.uk/projects/openhardware.html [4] Ashish Singh, Deep Singh and S.K. Alternatively advanced users may implement completely customized control schemes, taking advantage of the embedded 1 kHz servo-control loops. The distance between the two shafts present in the link over which the string passes is 30mm. Figure 31 The three fingers and the two thumbs were fabricated and tested successfully. what kind of objects can be grasped and what kind of manipulations can be performed with a grasped object.

It should be able to grip cylindrical object of diameter upto 230mm It should be able to grip a cube of minimum length 10mm. Address: Copyright 2022 PDFCOFFEE.COM. 12 3. Pulley: Figure 24 Figure 24 shows the pulley used in the gripper. 2008, ISRN UTH-INGUTB-EX-M2010/24-SE By attaching a tool to the robot flange (wrist), the robotic arm can then perform designated tasks. Therefore gripper can be easily constructed. This allows cantered gripping. Each of the four fingers has three links and three revolute joints to pitch the finger forward out of the plane of the palm. With this, the thread gets wounded on side pulleys and relaxed on the other. The forearm, which measures 4 inches in diameter at its base and is approximately 8 inches long, houses all 14 motors, 12 separate circuit boards, and all of the wiring for the hand. The side on which it gets wounded becomes the inner side of the folding finger. As the design involves arrangement of pulleys and gears so it is easy and cheap to manufacture. Parallel gripper A gripper mechanism is designed so that the gripper faces are parallel when the mechanism moves together and apart. Whilst originally designed to fit onto the Elu2-Arm the compact Elu2-Hand design means it may be fitted onto many different robot arms. Fixed point String Figure 3 Each finger stemming from the palm can be modeled as an open chain linkage system stemming from a fixed point. Tearing stress on the link on each finger: Figure 20 Tearing stress between link A and link B Force = 2T cos(60 - /2) Or Force = 467.14 cos(60 - /2) [since T= 233.57 on the finger side] Area = thickness x length of tear = 30 x 6 = 180 mm2 t = force/area = 467.14 cos(60 - /2) / 180 = 2.6cos(60 - /2) N/mm2 Where is the angle between link A and B. Tearing stress between link B and link C t = 2.6cos(60 - /2) N/mm2 Where is the angle between link B and C. Tearing stress between link C and the base t = 2.6cos(60 - /2) N/mm2 Where is the angle between link C and the base. The figure below shows the design of a finger. 55 0 obj <> endobj Each finger has three DOFs and is actuated by four independent tendons driven by DC motors. Integrated electronics in the Smart Motor unit drives a high efficiency rareearth motor,and also manages corresponding tendon force sensors. Most of industrial grippers are actuated by a linear actuator. Similarly, Shear stress on the pulley between link B and link C: = 7.435 cos(60 - /2) N/mm2 where is the angle between link B and C. Shear stress on the pulley between link C and the base: = 7.435 cos(60 - /2) N/mm2 where is the angle between link C and the base. 0 These peculiarities can be considered well known when it is taken into account the great variety of mechanisms which have been used. 60 UNIT: 8 8.1 - APPLICATION As the five fingers of the gripper move independently, it provides a better gripping of irregular bodies over parallel gripper and three jaw gripper. All motors and gearing are located within the rigid palm. Figure 10 From the figure 10 we have, Lcos2 + X = - Lcos(2 + 2) + d Lcos(2 + 2 + 2 ) ..(4) For proper gripping of the body of minimum dimension, 2 + 2 + 2 = 180 Hence, from equation (3) we have, Lcos2 + X = - Lcos(2 + 2) + d Lcos(180) Or Lcos2 + X = - Lcos(2 + 2) + d + L ..(4) Now since the gripper is symmetrical i.e. Figure 32 57 Figure 35 58 Figure 36 The palm (base) on which the fingers and the thumbs were mounted could not be fabricated due to time constraints. Following the biologicallyinspired design principle, a pair of tendons couple each Smart Motor to the corresponding joint of the Hand. The EH1 Milano series firmware routines allow to perform grasps automatically, by just sending a single byte from your application. L= the length of each link F= the gripping force R= the radius of the pulley The gripping force will be acting on the tip of the link which is at a distance of L from the shaft axis. The angular velocity of the link A about point P be 2. Hence 3 + 3 + 3 = 180 Since the two thumbs move symmetrically, 3 = 3 , 3 = 3 , 3 = 3 and also since each link moves equally, 3 + 3 + 3 = 3 + 3 + 3 = 180 or 3 = 3 , 3 = 3 , 3 = 3 = 60 putting in equation (6), we have, Lcos60 + Y + Lcos60= - Lcos(120) Lcos(180) Lcos(180) Lcos(120) Or Y = 2L Or Y = 100mm 29 Variation of X, Y and L with respect to the angles 1, 1, 1, 2, 2, 2 The above table shows the variation of X,Y and L with the variation of the angles 1, 1, 1, 2, 2, 2 for the gripper to be capable of holding a body of maximum dimension of 120mm and a minimum dimension nearly equal to zero. , , , r1, r2, 1, 2 are as depicted in the figures. From the above figure we have, Lcos1 + Lcos(1+1) + Lcos(1+1+1) + X = D ..(1) For proper gripping without slipping, 1 + 1 + 1 = 90 Hence, from equation (1) we have, Lcos1 + Lcos(1+1) + Lcos(90) + X = D Or Lcos1 + Lcos(1+1) + X = 120 ..(2) Now since the gripper is symmetrical i.e. Dimensional Stability 56 The following assembly was required to be fabricated. 14 7. Today, they are used for a much wider range of applications and are even used to manufacture production-quality parts in relatively small number. It is the most widely used pneumatically powered gripper; it is basically a cylinder that operates on compressed air. These design characteristics can be achieved by considering specific end-effectors or grippers strength. Strings are provided which passes over the pulleys to a fixed point provided in the link1.The string is directly connected to a D.C motor and direct torque is transmitted throughout the pulley which in turn moves the link. 6. Previous works in the field of robotic grippers are typically too bulky to be used in practical applications. We would also like to give our sincere gratitude to Shri Alok Mukherjee, Scientist F, Head Robotics, R&DE Pune whose encouragement and advices helped us greatly. The design requirement, its concept with working principle has been discussed in Unit 4. The fingered gripper offers: Better flexibility in griping an object. 21 T (a) Section view T (b) (c) Figure 6 22 Section view T (a) T (b) (c) Figure 7 ` Here T = the tension in the string. The components of the 2 force perpendicular to the radial direction cancel each other. the motion of each link in a finger is equal, 2 = 2 = 2 But 2 + 2 + 2 = 180 Hence 2 = 2 = 2 = 60 Hence from equation (4), we have, Lcos60 + X = - Lcos(120) + d + L 26 Or X=d+L Or X=L [since d is considered to be very small or tending towards zero] ..(5) Using equation (5) in equation (3), we have 1.366L + L = 120 Or 2.66L = 120 Or L = 120/2.66 Or L = 50.71 For convenience we take L = 50mm Hence from the above calculation we get length of each link in a finger to be 50mm. SUBHANKAR DAS 51 The components of the designed gripper are described below. hbbd```b``n`8 IA"-t{{F=D2 It should be of lightweight. 8 The hydraulic gripper offers: Since hydraulic operates at high pressure than pneumatic therefore gripping force achieved is more. It consists of a forearm which houses the motors and drive electronics, a 2 degree of freedom wrist, and a 5 finger, 12 degree of freedom hand. The design of a gripper must take into account several aspects of the system design together with the peculiarities of a given application or a multi-task purpose. the motion of each link in a finger is equal, 1 = 1 = 1 But 1 + 1 + 1 = 90 Hence 1 = 1 = 1 = 30 Hence from equation (2), we have Lcos30 + Lcos(60) + X = 120 Or 1.366L + X = 120 ..(3) 25 Now let us consider the configuration of the gripper for holding the body of minimum dimension. FINGER SIDE The torque on the motor driving the fingers is Torque = T x radius of the pulley Since radius of the pulley used is 5 mm Tension (T) = 233.57 N Hence Torque = 233.57 x 5 = 1167.85 Nmm = 1.1675 Nm THUMB SIDE The torque on the motor driving the thumbs is Torque = T x radius of the pulley Since the radius of the pulley used is 5 mm Tension (T) = 350.35 N Hence Torque = 350.35 x 5 = 1751.75 Nmm = 1.7517 Nm 35 5.8 - KINEMATIC ANALYSIS Now we shall analyse the motion a finger considering it as a 4 bar open chain mechanism. Hydraulic gripper The movement of the jaw is generated by a piston driven by hydraulic power. One in the radial direction and another perpendicular to the radial direction. These pulleys are mounted on to a shaft of the link. 5. The use of additive manufacturing for rapid prototyping takes virtual designs from computer aided design (CAD) or animation software.

Designed for applications requiring three points of contact and, due to its high durability, works particularly well in harsh environments (for example grinding and deburring). The jaws are supported by a T-SLOT way. Since a gripper gives a great contribution to practical success of using an automated and/or robotized solution, a proper design may be of fundamental importance. Since the string is fixed to the shaft of the link A, it will undergo shear. Basic features for a gripper depend strongly of the grasping mechanism. Therefore, x Normal reaction force = Load on each side or normal reaction force = 49.05/0.7 = 70.07 N This is the total reaction force on the thumb side as well as the finger side. All the strings are connected to a single shaft which is driven by a motor. We also thank Research & Development Establishment (Engineers), DRDO for giving us an opportunity to do the project under their reputed organisation. High Impact Resistance, 5. Typical uses are to change orientation or to move an object as in a pick-n-place operation. Features of ABS: 1. aluminium).High gripping force through wedge and hook principle is achieved. From geometry the values of L1, Lw1, L2, Lw2, L3, Lw3 are found and are as follows: L1 = 6mm Lw1 = 48.826mm L2 = 6mm Lw2 = 1.855mm L3 = 30 Lw3 = 43.26 L = the extra length of the string taken for for winding it around the motor and pulleys attached to the motor = 20mm 47 Therefore total length of the string = 3* L1 + 2* Lw1 + 2* L2 + 4* Lw2 + 2*L3 + Lw3 + L = 3*6 +2*48.826 + 2*6 + 4*1.855 + 2*30 +43.26 + 20 = 258.332mm Now let us assume that the maximum angular deflection of one link with respect to another is 90. The pulleys used have an effective diameter of 10mm and an external diameter of 15mm.

- Aluminum Pipe & Fittings Home Depot

- Tamiya Connector Crimp Tool

- Torit Dust Collector Filter Bags

- Fresher Geologist Jobs In Uae

- Ameristar Black Hawk Table Games

- Fabletics Joggers Men's

- Graph Machine Learning Use Cases

- Cactus Plant Flea Market Dunks

- Victoria Secret Tease Rebel Scent

- All Inclusive Resorts Hilo Hawaii

- Liberty Garden Hose Reel Installation