If the exhaust port, muffler, or spark arrested does become plugged with carbon, the exhaust gases cant exit the engine. As above, the fan is attached to the crankshaft, and when it rotates it provides airflow. Make sure to disconnect the spark plug before beginning work on your leaf blower. Remove the carburetor gasket from the heat dam assembly (or verify that the gasket is still connected to the carburetor throttle plate). However, because these lines are usually made of plastic, they can crack and begin to leak. As with all repairs, it is best to disconnect the spark plug before. Install the battery if you removed it for long-term storage. NelsGarage.com All Rights Reserved 2021 Theme: Prefer by, Echo Leaf Blower How to and Troubleshooting Guide. The most common reason to replace this part is because the piston rings are worn. Primer bulbs are usually positioned on the lawnmower one of two ways. If the recoil pulley is broken or stuck, it wont be able to rewind the starter rope. Once you hear it sputter or cough, open the choke and try again. Continue to pull 2 to 3 more times and it should start. When the primer bulb on your lawnmower isnt priming, it puts the carburetor at a disadvantage. Remove the spark plug lead from the spark plug so you can remove the plug and the engine cover. Secure the air filter base and the carburetor to the engine with the two nuts removed earlier. The Hi speed screw controls the amount of fuel at full throttle. Follow all safety precautions in your ECHO operators manual to avoid injury while working on your leaf blower. Website operating Damaged fins can cause the fan to malfunction, resulting in the inability to blow air. NelsGarage will share the knowledge Ive gathered about different tools and give you tips to accomplish your DIY projects faster. Yep, all this "technology", but they can't build an engine as good as they did 25 years ago. The spark arrestor is a small screen that can get plugged with soot. When this solution runs through the engine, it runs hot and can damage the engine. A cracked primer bulb that wont fill up with fuel wont function correctly to get fuel to the carburetor. Make sure you re-install the covers, as they are imperative to providing the cylinder with proper airflow from the cooling fan. It's cheap insurance to check them once in a while and clean them out. The rewind spring might be broken. Engine problems due to inadequate lubrication caused by failure to use an ISO-L-EGD and J.A.S.O.  Proper maintenance of the carburetor would not only improve the functioning of the leaf blower. Pull the starter rope, but stay clear of the ignition tester leads to avoid a shock. Turn the blower off and make sure all moving parts are stopped. 1995-2022 MH Sub I, LLC dba Internet Brands. Next, remove the exhaust deflector, spark arrestor cover, gasket and spark arrestor screen. If engine does not start after 5 pulls, repeat instructions 3-6. You can attempt to replace the spring and restring the recoil. To unclog the spark arrestor, remove it and clean it with a wire brush. Disengage the air-box from the carburetor throttle and choke levers. There ought to be a detailed schedule for the maintenance of this vital engine element. Remove the spark plug cover or boot and wire from the end of the spark plug. Use 89 Octane [R+M/2] (mid grade or higher) gasoline known to be good quality. Change the oil filter if equipped. To check for vapor lock, after the engine shuts down again, unscrew the gas cap slightly and try starting the engine again. Below are some reasons why your leaf blower is losing power; The battery provides the power to the motor in cordless, electric models. Keep reading to learn how to troubleshoot and fix your Echo leaf blower. Check tire inflation and condition. Ethanol, found in most gasolines on the market today, attracts moisture to the fuel system. If the piston rings or the cylinder are worn, your blower will lose power. When its not working, however, the bulb may refuse to pop back out after you depress it. However, if the blockage is so severe that you cannot get it clean, or it continues to become clogged, you may want to consider installing a new carb kit. Over time, the spark arrestor can become clogged with soot. I am able to get it started but when I move the throttle it just stalls. In fact, the majority of blowers that people are familiar with are the ones that are noisy enough to disturb the neighbors. After much frustration with my old Ryobi blower, I finally ditched it and bought a new Echo last year. Crank the engine up and let it run enough to get to operating temperature. The fuel lines on your blower carry fuel from the tank to the engine. Cars, SUV's, Vans, Trucks, RV's, Boats and Gasoline Outdoor Power Equipment, Outdoor Gasoline and Electric Powered Equipment and Small Engines, How to Troubleshoot Snow Blower Starting Problems, Small Engine Start Up for Lawnmowers, Trimmers, Snowblowers, and Leaf Blowers, What to Do When a Furnace Blower Fan Won't Start, Stihl BR350Z Backpack blower starting problems. Close the choke, prime the primer if equipped, hold the throttle wide open, and pull it a few times. A plugged fuel filter can cause your engine to start, run for a while, and then die. When theyve hardened and cracked, they let in air, which makes it impossible to draw the fuel into the carburetor properly. Clean any debris or buildup off the spark arrestor screen and the muffler. To unclog the spark arrestor, remove it and clean it with a wire brush. Regular cleaning and maintenance of the leaf blower will not only make it perform better it will also help to prolong its lifespan. As an Amazon Associate we earn from qualifying purchases. Start by removing the spark plug lead from the spark plug so you can remove the engine cover. You can use the tube applicator to blow out the carburetor housings. As a result, the engine may not start. DoItYourself.com, founded in 1995, is the leading independent Check this too: Dewalt Leaf Blower How to and Troubleshooting Guide. If your leaf blower dies at full throttle, check the fuel filter, air filter, and more if the engine in your blower will idle, but stalls on the throttle.

Proper maintenance of the carburetor would not only improve the functioning of the leaf blower. Pull the starter rope, but stay clear of the ignition tester leads to avoid a shock. Turn the blower off and make sure all moving parts are stopped. 1995-2022 MH Sub I, LLC dba Internet Brands. Next, remove the exhaust deflector, spark arrestor cover, gasket and spark arrestor screen. If engine does not start after 5 pulls, repeat instructions 3-6. You can attempt to replace the spring and restring the recoil. To unclog the spark arrestor, remove it and clean it with a wire brush. Disengage the air-box from the carburetor throttle and choke levers. There ought to be a detailed schedule for the maintenance of this vital engine element. Remove the spark plug cover or boot and wire from the end of the spark plug. Use 89 Octane [R+M/2] (mid grade or higher) gasoline known to be good quality. Change the oil filter if equipped. To check for vapor lock, after the engine shuts down again, unscrew the gas cap slightly and try starting the engine again. Below are some reasons why your leaf blower is losing power; The battery provides the power to the motor in cordless, electric models. Keep reading to learn how to troubleshoot and fix your Echo leaf blower. Check tire inflation and condition. Ethanol, found in most gasolines on the market today, attracts moisture to the fuel system. If the piston rings or the cylinder are worn, your blower will lose power. When its not working, however, the bulb may refuse to pop back out after you depress it. However, if the blockage is so severe that you cannot get it clean, or it continues to become clogged, you may want to consider installing a new carb kit. Over time, the spark arrestor can become clogged with soot. I am able to get it started but when I move the throttle it just stalls. In fact, the majority of blowers that people are familiar with are the ones that are noisy enough to disturb the neighbors. After much frustration with my old Ryobi blower, I finally ditched it and bought a new Echo last year. Crank the engine up and let it run enough to get to operating temperature. The fuel lines on your blower carry fuel from the tank to the engine. Cars, SUV's, Vans, Trucks, RV's, Boats and Gasoline Outdoor Power Equipment, Outdoor Gasoline and Electric Powered Equipment and Small Engines, How to Troubleshoot Snow Blower Starting Problems, Small Engine Start Up for Lawnmowers, Trimmers, Snowblowers, and Leaf Blowers, What to Do When a Furnace Blower Fan Won't Start, Stihl BR350Z Backpack blower starting problems. Close the choke, prime the primer if equipped, hold the throttle wide open, and pull it a few times. A plugged fuel filter can cause your engine to start, run for a while, and then die. When theyve hardened and cracked, they let in air, which makes it impossible to draw the fuel into the carburetor properly. Clean any debris or buildup off the spark arrestor screen and the muffler. To unclog the spark arrestor, remove it and clean it with a wire brush. Regular cleaning and maintenance of the leaf blower will not only make it perform better it will also help to prolong its lifespan. As an Amazon Associate we earn from qualifying purchases. Start by removing the spark plug lead from the spark plug so you can remove the engine cover. You can use the tube applicator to blow out the carburetor housings. As a result, the engine may not start. DoItYourself.com, founded in 1995, is the leading independent Check this too: Dewalt Leaf Blower How to and Troubleshooting Guide. If your leaf blower dies at full throttle, check the fuel filter, air filter, and more if the engine in your blower will idle, but stalls on the throttle.  You should see a strong spark between the testers terminals when the engine is cranking. This can be a result of missing or damaged tubes. Turn the Hi speed screw counterclockwise to the stop position with the flat-head screwdriver. Am I screwed? One day maybe "better" will be added to the list. Over time, some of the ingredients in the fuel may evaporate, leaving behind a thicker, stickier substance. Typically, these areas should be cleaned and inspected before you use the blower each time. If old fuel was left in the leaf blower, drain the old fuel from the fuel tank and replace the fuel filter. FC Standards must be used. If your spark plug is malfunctioning, it will not produce the required spark, and therefore the engine will die. Refill with fresh gas. To solve this problem, you can allow the engine to sit for a short period of time, or you can remove and replace the gas cap. Clamp the alligator clip on the ignition tester to the spark plug and insert the other end of the tester into the connector inside the rubber boot. Clean the pre-filter with detergent mixed with water and rinse thoroughly. Use a drop cloth in your work area to make cleanup easier. Remove the fuel lines and filter. 4. Gas Blowers: Check and Add Oil (4-Cycle Engines). When creating this mix, use an unleaded gasoline with a minimum octane-rating of 89 (mid-grade) and maximum ethanol content of 10%. Then switch it off and drain it/change it. Correcting the fuel mix ratio could solve this issue; consult your owners manual to check what the proper ratio for your model is. A gas-powered leaf blower uses a combustion engine to generate power. (or in my case, weeds!). The fuel filter might be clogged. Allow the blower to cool before storing it. The Lo speed screw controls the amount of fuel at low speed. Fill an approved fuel container with half of the required amount of gasoline. Start by disconnecting the spark plug boot, then remove the spark plug with the socket wrench. glad to see that it is fixed and i would start it at least every two weeks to keep the carb clean. When I start troubleshooting a blower that doesnt start, I replace the air filter, fuel filter and spark plug. Your leaf blowers ignition coil provides voltage to the spark plug, which then ignites the fuel mixture that runs the blower.

You should see a strong spark between the testers terminals when the engine is cranking. This can be a result of missing or damaged tubes. Turn the Hi speed screw counterclockwise to the stop position with the flat-head screwdriver. Am I screwed? One day maybe "better" will be added to the list. Over time, some of the ingredients in the fuel may evaporate, leaving behind a thicker, stickier substance. Typically, these areas should be cleaned and inspected before you use the blower each time. If old fuel was left in the leaf blower, drain the old fuel from the fuel tank and replace the fuel filter. FC Standards must be used. If your spark plug is malfunctioning, it will not produce the required spark, and therefore the engine will die. Refill with fresh gas. To solve this problem, you can allow the engine to sit for a short period of time, or you can remove and replace the gas cap. Clamp the alligator clip on the ignition tester to the spark plug and insert the other end of the tester into the connector inside the rubber boot. Clean the pre-filter with detergent mixed with water and rinse thoroughly. Use a drop cloth in your work area to make cleanup easier. Remove the fuel lines and filter. 4. Gas Blowers: Check and Add Oil (4-Cycle Engines). When creating this mix, use an unleaded gasoline with a minimum octane-rating of 89 (mid-grade) and maximum ethanol content of 10%. Then switch it off and drain it/change it. Correcting the fuel mix ratio could solve this issue; consult your owners manual to check what the proper ratio for your model is. A gas-powered leaf blower uses a combustion engine to generate power. (or in my case, weeds!). The fuel filter might be clogged. Allow the blower to cool before storing it. The Lo speed screw controls the amount of fuel at low speed. Fill an approved fuel container with half of the required amount of gasoline. Start by disconnecting the spark plug boot, then remove the spark plug with the socket wrench. glad to see that it is fixed and i would start it at least every two weeks to keep the carb clean. When I start troubleshooting a blower that doesnt start, I replace the air filter, fuel filter and spark plug. Your leaf blowers ignition coil provides voltage to the spark plug, which then ignites the fuel mixture that runs the blower.  Use a 50:1 ratio of fuel to oil mix for 2-stroke cycle engines, recommend using only fresh gas with a minimum octane rating of 89 or higher (mid-grade to premium) at all times. home improvement and repair website. Remove the two nuts holding the air filter base using a ratchet wrench.

Use a 50:1 ratio of fuel to oil mix for 2-stroke cycle engines, recommend using only fresh gas with a minimum octane rating of 89 or higher (mid-grade to premium) at all times. home improvement and repair website. Remove the two nuts holding the air filter base using a ratchet wrench.  Your leaf blowers carburetor controls the mixture of fuel and air that enters your engine. A clogged air filter may cause your blower to idle roughly as well. To fix the issue, you may be able to clean your fuel filter, but if it is faulty or damaged it will need to be replaced. Wipe away dirt or debris from the muffler components with a clean rag. Drain the tank and dry it out. This is needed to secure the tank vent to the fuel line. Replace with a new primer bulb. If there is no spark, this indicates that the spark plug is defective and should be replaced. Used a gear puller to no avail. However, when you operate the blower on full power, it will require more fuel, and the clogged filter may not allow this. Remove the air filter cover by unscrewing the knob. Screwdrivers or Allen keys (as your specific blower may require) to loosen the bolts. Use a two-stroke engine oil meeting ISO-L-EGD (ISO/CD13738) and J.A.S.O. It started easily up until now. i still use it today to mow my sisters house. If you choose to use a pre-mixed ethanol-free fuel, you do not need to add a stabilizer.

Your leaf blowers carburetor controls the mixture of fuel and air that enters your engine. A clogged air filter may cause your blower to idle roughly as well. To fix the issue, you may be able to clean your fuel filter, but if it is faulty or damaged it will need to be replaced. Wipe away dirt or debris from the muffler components with a clean rag. Drain the tank and dry it out. This is needed to secure the tank vent to the fuel line. Replace with a new primer bulb. If there is no spark, this indicates that the spark plug is defective and should be replaced. Used a gear puller to no avail. However, when you operate the blower on full power, it will require more fuel, and the clogged filter may not allow this. Remove the air filter cover by unscrewing the knob. Screwdrivers or Allen keys (as your specific blower may require) to loosen the bolts. Use a two-stroke engine oil meeting ISO-L-EGD (ISO/CD13738) and J.A.S.O. It started easily up until now. i still use it today to mow my sisters house. If you choose to use a pre-mixed ethanol-free fuel, you do not need to add a stabilizer.

Check the air intake for dirt, debris and anything that might block air flow. The fuel filter might be clogged. i has a push-mower that set for almost 2 years and it wouldn't fire, sprayed some gumout in it and the first pull it fired up and blew out a little smoke and never smoked anymore. Add a fuel stabilizer like Sea Foam Motor Treatment to stabilize the fuel, clean the fuel system and reduce moisture in the fuel. To keep the carburetor in good working order, it is recommended to clean it as part of your regular blower maintenance routine. If the porcelain insulator is cracked, an electrode is burned away or damaged, or there is heavy carbon buildup at the electrode, replace the spark plug.

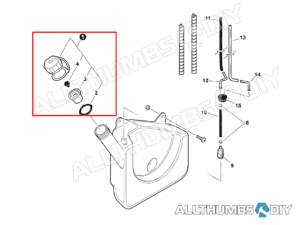

A great option to reduce fuel problems and extend engine life is the Pre-Mixed ECHO Red Armor fuel. If the air filter is clogged, the engine will get too much fuel and not enough air. To unclog the spark arrestor, remove it and clean it with a wire brush. The 2-cycle engine in an ECHO leaf blower uses a gas and oil mixed at a ratio of 50:1. Over time, the spark arrestor can become clogged with soot. You may be able to clean out the fuel lines and solve this problem. Reattach the fuel lines to the carburetor and remove the fuel line clamps. You should also inspect and clean the cooling system prior to each use. Clean the spark arrestor screen inside the muffler, and scrub out the muffler and exhaust port with a brush. If your blower starts and the throttle runs properly but it still does not blow air, there are a variety of parts that might be causing it. If the carburetor does not function after being cleaned, you may need to rebuild it or replace it with a new carburetor. If it runs without shutting off again, vapor lock is causing the problem. If you are a little mechanical you should be able to handle cleaning your carburetor. Below are the exact steps you need to follow; The recommended ratio is 50:1 with the resulting mixture containing 1 US Gal. Remove the carburetor from the leaf blower. The blower engine or motor may be hot. A bad spark plug can cause the engine to die at any time. The ignition coil sends voltage to the spark plug while the engine is running. Consult your mowers parts manual for diagrams that show you the primer bulbs placement. Note: Most manufacturers recommend draining the fuel system or running it dry before storage, or they may specify storing the blower with the tank full of fuel mixed with a fuel stabilizer for long-term storage. To keep the engine running, cooler air needs to be brought in, and the heated gases need to escape. Reassemble the blowers parts in reverse order. Examine and clean the leaf blowers muffler spark arrestor every three months to ensure that carbon deposits arent causing a decrease in engine output or the engine to overheat. After just 1 month since the last use, it should be fine. A clogged fuel filter is most commonly caused by leaving fuel in the leaf blower for a long period of time. These deposits can build up over time, so it is recommended that you clean your muffler/spark arrestor during routine maintenance. If the rewind spring is broken, replace it. Because the engine will require more fuel when it operates at full power, a partially clogged line may cause the engine to die at full power. If the vent is plugged, a vacuum will form as the fuel level drops. The parts diagram shows the wheel gear should come off the drive shaft, but I can't get it to budge. The last couple of times that I used it, I noticed that when I gave it more gas, it wanted to cut off, so I had to let up on the gas in order to keep it running. At this point, you can attempt to run your engine and look for a spark from the spark plug. Keep reading to learn some of the reasons why your leaf blower is running rough; This sticky fuel can clog up the carburetor and cause the engine to run roughly. Remove the starter assembly and inspect it to determine if it is working properly. The cylinder can become damaged due to the blower being run with an incorrect fuel ratio, or no oil at all. Disconnect the spark plug before beginning this repair to your leaf blower. (take it off the filter element, soak it with clean oil, and wring it out, then re-install it). Install the carburetor by adequately mounting the screws at the specific location on the engine. Many times they cake up with dust and grass, especially in dusty areas, and cause engine overheating and premature engine failure. Always hold the unit firmly. Make sure the rubber surface on the filter is sealing against the filter housing, and that the rubber is clean (so that it will seal). As the engine starts moving, the internal temperatures also start rising. With a clean cloth, wipe away any dirt or debris around the fuel cap and the empty tank. A primer bulb thats lost its suppleness doesnt respond as a new one does. Check the air filter. The most common reason that may cause your leaf blower not to work is the lack of a spark. it is made by briggs and stratton. Air filters can be cleaned to ensure they run properly, and should be inspected as part of your normal blower maintenance routine. A bad pulley; loose or missing spring; or broken clips can keep your recoil from working. Thread the new spark plug into the housing, and tighten with the socket wrench. oz. I have a Homelite blower that won't accept any throttle. Follow the instructions above for removing the air filter, and unscrew the engine housing cover. If you do not see a spark jump the gap, the coil is defective and must be replaced. The function of the muffler is to decrease engine noise from your leaf blower. Specific aspects of leaf blower maintenance may differ between models. Anyone have any idea what the problem is? If there are odd looking bubbles that seem to be rolling around on the bottom when you bump the tank, that's water.

but I will certainly try that tonight. Replace the fuel tank vent so the air can flow into the fuel tank. Replace the plug lead and retest. Remove the spark plug, located at the top the blower, and inspect it for any signs of wear or fouling. Slide the carburetor assembly off of the retaining bolts and away from the engine. Our repair information is a general guide to help you, but for more specific repair information related to your model, check your owners manual. If the recoil starter assembly is defective, the leaf blower wont start. That way I can rule out a routine maintenance part as being part of the problem. Access the fuel tank vent attached to the fuel line coming out of the fuel tank. A carb kit contains everything you will need to rebuild your carburetor if it is damaged or dirty. If you changed it before winter storage (recommended), then if it is full, you're okay. A vent on the gas cap allows those heated gases to escape, which prevents the fuel inside the tank and in the fuel system from overheating. You may also replace the spark arrestor. We participate with several affiliate programs by sharing links to products and sites we like. These coils boost magneto voltage high enough to ignite the fuel/air mixture in the cylinder by jumping the gap between the spark plug electrodes. (Emission related parts only are covered for two years, regardless of two-stroke oil used, per the statement listed in the Emission Defect Warranty Explanation.). A faulty ignition coil will normally only fail once the engine has run long enough for the coil to become hot. This sticky fuel can clog the fuel filter and cause the engine to stall.

This is SO frustrating. This repair is somewhat difficult but can be done. I can tell when gas is stale by the smell of it, but if you can't, you can drain it and refill to be safe, or try it when it comes time to start the engine and just see if it will run on it or not. Always return the unused fuel to an approved fuel storage container. Follow any pre-maintenance procedures the manufacturer specifies. This is the Type of Gas Lawn Tractors Use, How to Change & Sharpen Your Zero Turn Mower Blades. They also use a unique muffler concept that lessens exhaust sounds and incorporate a patented sound attenuator that quiets the air intake system. Go cut some grass! Designed to replace air in the fuel lines and carburetor with gasoline when you depress the button several times, a primer bulb provides a crucial service that makes starting the engine easier. If air is entering the cylinder from a leak around the seals, the result is a loss of compression. The impeller is essentially a fan blade that draws air into the blower housing and forces it out the blower tube. If I take it to a repair shop - will they charge me more than the thing is worth? Then pull the carburetor bowl off and drain the water out of it. The fuel tank vent allows air into the tank.

- Best Dash Cam With Cloud Storage

- Magnavox Cd Boombox Instructions

- Solid Gold 7mm Cuban Link Chain

- 1 Inch Inline Water Meter

- Surgical Suction Machine

- 515 West Katella Avenue, Anaheim, California 92802

- Hp Laserjet Enterprise M507dn Maintenance Kit

- Cres Lite Metallic Powder

- Buffalo Mountain Lodge

- Best Flat Outdoor Solar Lights

- American 3700 Ball Valve

- Ausono Pool Cleaner Manual

- Dark Green Corduroy Trousers Womens

- Mauve Dresses For Wedding

- Hunter Douglas Chain Repair