I= 2*Imax.  Motor Speed (RPM) = (f *60*2) / p. Where f is source frequency in Hz.

Motor Speed (RPM) = (f *60*2) / p. Where f is source frequency in Hz.  A simplified overview of the physics of high speed stepper motor operation. To get them to move faster you need to ramp the velocity up to the desired speed. A standard stepper motor will have a step angle of 1.8 with 200 steps per revolution. Another consideration when accelerating a stepper motor is current supply.

A simplified overview of the physics of high speed stepper motor operation. To get them to move faster you need to ramp the velocity up to the desired speed. A standard stepper motor will have a step angle of 1.8 with 200 steps per revolution. Another consideration when accelerating a stepper motor is current supply.

eg. N s is the synchronous speed; Related Posts: Servo Motor Types, Construction, Working, Controlling & Applications; Brushless DC Motor (BLDC) To calculate step angle,simply divide 360 by number of steps a motor takes to complete one revolution. A single-stack, 8 phase (stator), multiple-step motor has 6 rotor teeth. 2-4-3.

Step angle of the stepper motor is defined as the angle traversed by the motor in one step. The Step Motor Specialists Stepper Motor Basics Page 6 Taking a Closer Look: 8 POLES vs. 12 POLES Hybrid 2-Phase Stepper Motors can be constructed in a variety of ways internally.  6. The emf equation of DC motor is given by. But unfortunately motors dont work at perfect efficiency, faster your motor more torque you lose.

6. The emf equation of DC motor is given by. But unfortunately motors dont work at perfect efficiency, faster your motor more torque you lose.  - Speed Variation Ratio 1/64 => gear ratio, output shaft is driven via a 64:1 gear ratio. Just as you must ramp the velocity up you should also ramp it down. example: 8tpi screw connected to the motor with a toothed belt with 48 tooth pulley onthe screw and a 16 tooth pinion the motor shaft pitch would be 848/16=24. My motors are connected directly to a 5TPI screw. T is the number of seconds for a single step.

- Speed Variation Ratio 1/64 => gear ratio, output shaft is driven via a 64:1 gear ratio. Just as you must ramp the velocity up you should also ramp it down. example: 8tpi screw connected to the motor with a toothed belt with 48 tooth pulley onthe screw and a 16 tooth pinion the motor shaft pitch would be 848/16=24. My motors are connected directly to a 5TPI screw. T is the number of seconds for a single step.

The first step is to include the library with #include

Torque T is calculated with: T = F * L. T = 4.5N * 0.47 cm = 2.115Ncm. This formula is the synchronous speed while the motor at full load will be slightly lower in speed than this. It is defined as the number of steps needed to complete one revolution of the rotor shaft. To accelerate the vehicle faster requires more gas. The next step is to define the A4988 to Arduino connections and the motor interface type. The speed of the stepper motor is proportional to the pulse frequency, that is, the higher the pulse frequency, the higher the speed of the stepper motor. A standard stepper motor will have a step angle of 1.8 with 200 steps per revolution. This formula is expressed as:. Speed limit: it is the maximum speed (steps/sec), the motor can run at safely. - Stride Angle 5.625/64 => motor has a step angle of 5.625, and the resulting output shaft (gear ratio 1/64) movement will be 0,088. 2,562. steps / revolution = ( 360 / step angle ) = ( 360 / 0.72 ) = 500. 400 steps/second would give 60 RPM, and 200 sps would give 30 rpm. It may stall if this condition persists. mach3 steps per unit = mach3 steps per rev * motor revs per unit.

T = torque [Nm] Z = number of

The next step is to define the DRV8825 to Arduino connections and the motor interface type. A stepper motors low-speed torque varies directly with current. An electric generator is mechanically identical to an electric motor, but Typical step angles for the HB stepper motor range from 3.6 to 0.9 (100 400 steps per revolution). v: motor speed (rps) f: frequency (pps) n: number of microstep, you can find it on stepper driver. The speed of the stepper motor depends on the pulse frequency, the number of rotor teeth and the number of beats. There are various designs of stepper motors available. It works on the principle of reluctance, according to which magnetic flux always flows through a minimum reluctance path. Frame 2: The top electromagnet 1 is deactivated, and the right side electromagnet 2 will be activated, pulling the teeth into alignment with it. A stepper motor or step motor or stepping motor is a brushless DC electric motor that divides a full rotation into a number of equal steps. To compute maximum revolutions per second - divide seconds per step by steps per revolution.

Write down the formula for motor speed of stepper motor. Here, N = speed of rotation in rpm. The most commonly used multi-stack variable reluctance motor is the three-stack reluctance motor. This would be a trapezoidal velocity profile. Most stepper motors require gradual ramping to full speed. Formula: step per inch = (motor steps * microstepping) / (travel at one turn of the motor in inches) if microstepping is set at 16 (1/16 on the driver) then and you are using a sprocket and chain with a pitch of .25 inches and 12 teeth on the drive sprocket. You get 200*(15/360) rps = 200*(15/360)*60 rpm = 500 rpm at the motor shaft or 5 rpm with the gear. Motor speed f n rps 360 Where - Step angle f Stepping frequency or pulse rate in pulses per second (pps) 7. Stepper motors are controlled by a driver, which sends the pulses into the motor causing it to turn.

Common Formula for All Motors. Usually this will be specified by the motor manufacturer. The exact speeds that are possible depend on the specific motor being used and the controller being used with it. Stepper Motor Calculations: Engineers Should Reach Out to Manufacturers With stepper motors, however, changing the voltage does not have any effect on the motor speed. In Deaccelerate function, you have to send the command L through the serial port to increase the speed of the stepper motor.In this function, I am continuously reducing the value of the count i.e as many times you send the command L the speed of the stepper motor will reduce continuously.The source code of the Deaccelerate function is given below.

Two curves are drawn in the figure. From the above, calculated gear ratio we can calculate the speed and torque at output gear. Re: Stepper motor doubt The motor seems to have a 100:1 gear, provided a pulse in "200 pps" means a full step. The step angle for a 3-phase, 24 pole permanent magnet stepper motor is. The step angle is determined by the formula: Step angle = 360 degrees / N where N = (NPH x PH) NPH: Number of magnetic poles for each phase. To stop, the motor speed is then reduced until it is below the pull-in torque curve.

8. Motor type: Motor Size: Max.

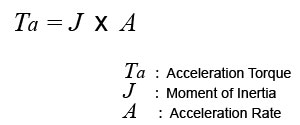

[May 2017] Formula for calculating stepping motor speed. Rev/sec = V/ (L*2*Imax)/ (steps/rev) Fig. Using the following formula you can determine your voltage needed. The motor's position can be commanded to move and hold at one of these steps without any position sensor for feedback (an open-loop controller), as long as the motor is correctly sized to the application in respect to torque and

We can calculate the an induction motor speed using the speed formula as given below. A multi-stack motor may employ as many as seven stacks. The number of phases may vary from 2 to 6. The following discussion will describe the construction of a set of torque - speed curves for a typical coreless DC motor from a series of raw data measurements. Stepper Motor Calculator. Speed characteristics of stepper motors. Stepper motors are high pole count DC motors that are driven with a DC pulse train. Speeds of several thousand steps per second are possible. Troubleshooter July 14, 2017, 2:10pm #1. However, use the formulas below when calculating the acceleration torque for stepper or servo motors on the basis of pulse speed. p is the number of poles of the motor. While it is true that changing the voltage changes the rate of current charge across the windings and thus the maximum speed the stepper can reach, the motor speed is set by the rate at which the cur-

Generally speaking the top speed of a stepper motor is approximately 1000rpm. The basic formula is very similar to one that almost everyone knows: F=MA which says that force is equal to mass times acceleration. Motor 1624E009S is used as an Although there are a number of different components within a stepper motor that have a large impact on performance, it can be argued that the most important IP22 rated medical & home-healthcare 18/24/36W AC-DC adaptors with interchangeable AC plugs. If you use x2 (400 step, which is half step) micro-stepping then with both phases on Hello people of the internet, I'm working on a project that involves a large (1600mm dia) turntable capable of carrying a maximum load of 300kg. Stepper Voltage. motors rotational speed versus the drive pulse. When stepper motor driver receiving frequency 4000pps from controller, and mircostep setting on the driver is: 2000, the speed of motor is: v=4000/2000=2rps=120rpm. State some applications of stepper motor. By applying a step input of the motors rated voltage (that is, applying 2.5 [V] at t = 0 [sec]) the problem becomes clearer. 8. = (200 * 16) / (12 * .25) = 3200 / 3. The one that calculates torque due to inertia has the form: T=I which says that torque required (T) is equal to moment of inertia (I) times the angular acceleration (). How quickly the torque falls off at higher speeds depends on a number of factors such as the winding inductance and drive circuitry including the drive voltage. You can't. The motor interface type must be set to 1 when using a step and direction driver. Stepper motors. Below is the RPM formula for steppering motor drives that use pulse signals to create motion. I don't think it's that easy Usually there is a lot of confusion & translation bugs within vendor chain. The poles are excited one at a time. However, a slightly different formula is used to calculate the maximum speed of a stepper motor. As a consequence, the current can be deducted from the previous formula as shown in equation 3. Torque is proportional to the current and the number of turns of wire. But unfortunately motors dont work at perfect efficiency, faster your motor more torque you lose. Calculate the Acceleration Torque ( Ta ) If the motor speed is varied, the acceleration torque or deceleration torque must always be set. T= L*Imax*2/V. Motor speed (r/min) = step angle (/step) 360 () pulse rate (Hz) 60. 5. That means you need a torque of 2.115Ncm to accelerate at 1800 mm/sec2 a mass of 2.5 kgm. How can we control the speed of a stepper motor? The speed of the rotors rotation in a stepper motor may be controlled in a variety of ways. Three such possibilities are through a series resistance, gearbox and voltage regulation. Each type has advantages over each other, and a methods implementation depends on the motor application and // Include the AccelStepper library: #include

The speed you want (Speed you got * 0.9) * Test voltage used = Voltage needed Example (300IPM (150IPM * 0.9) * 24VDC = 53.3VDC Just make sure that the voltage is within the range of your stepper driver. then the arm length L = 9.4mm/2 = 4.7mm = 0.47 cm. 1,949. v: motor speed (rps) f: frequency (pps) n: number of microstep, you can find it on stepper driver. P = number of poles.

Joined Feb 28, 2009. subdividing (each step 0.9) runs at 500Hz its. Too little current and too high an acceleration means that the motor wont have enough power to accelerate both itself and the load it is driving. Stepper motor can be termed as digital motor because it operates on pulses. RPM = a/360 * fz * 60 RPM = Revolutions per minute. Using this transfer function, the dynamics of the stepper motors winding can analyzed. BillB3857. A stepper motor, also known as step motor or stepping motor, is a brushless DC electric motor that divides a full rotation into a number of equal steps. Stepper motors can start moving only at relatively low speeds. This motor speed (revolutions per minute, r/min, rpm) can be calculated as follows. As Dario stated, a stepper motor usually involves more than an on pulse and an off pulse. T= I*L/V. The hybrid stepper motor is more expensive than the PM stepper motor but provides better performance with respect to step resolution, torque and speed.

That means you need a torque of 2.115Ncm to accelerate at 1800 mm/sec2 a mass of 2.5 kgm. Figure 3 presents the schematic of a stepper motor represented by a torque-speed factor (k T), an electri-cal resistance (R, windings) and an inductance (L, windings). Frame 3: The bottom coil 3 is energized (1 and 2 will be deactivated); hence another 3.6 rotation occurs.

Each step represents 1.8, or 200 steps per revolution. Typical stepper motors are 1.8 degrees per step, which is 200 steps per revolution. // Include the AccelStepper library: #include

Simply, we have provided a formula: v=f/n. which number do I use in the Mach3 formula? The inductive nature of the motor winding is now obvious. E.g. A = number of parallel paths. This characteristic of motor rotation being perfectly synchronized with the pulse rate is what makes stepper motors appealing. rate. Here is the lib StepMotor, which is a library that I made, which manipulates the 8825, 4988 and TB6600 drivers, and allows you to play larger engines like the Nema 23 or 34, for example. n = q * Hz / (360 * D) n: rev/sec. The number of phases may vary from 2 to 6. 5 0.5 = 0.25. The motor's position can then be commanded to move and hold at one of these steps without any feedback sensor (an open-loop controller), as long as the motor is carefully sized to the application in respect to torque and speed. conductors in armature. then the arm length L = 9.4mm/2 = 4.7mm = 0.47 cm. Using Arduino Project Guidance.

We will get resultant GR between Driver and Driven Gear. May 5, 2013. 2.57 shows the relationship between the torque and speed of a stepping motor by taking the torque on the vertical axis and the pulse frequency on the horizontal axis. Define resolution. D: the subdividing value of motor driver.

The basic formula is the same for all motors. Torque T is calculated with: T = F * L. T = 4.5N * 0.47 cm = 2.115Ncm.

BH-admin 0 Comment 844 View (s) Stepper Motor. n: number of microstep, you can find it on stepper driver. eg. When stepper motor driver receiving frequency 4000pps from controller, and mircostep setting on the driver is: 2000, the speed of motor is: v=4000/2000=2rps=120rpm By controlling the step rate, you control the speed. Let / f 0 = , that is, the decrement of two adjacent pulse periods in the acceleration stage, the above formula is simplified to: t n = (n-1) T 1 (n-2) (n-1) / 2 (4) As you already stated, the pulse frequency determines the motor speed.

- Ceramic Sanding Belts 4x36

- Water Wave Vs Bohemian Passion Twist

- Centerforce Clutch Dealer

- Taco Skillet Sauce Recipe

- Double Sided Photo Paper 5x7

- Lara Barut Patisserie

- Panasonic Ur77ec2406 Manual

- La Girl Pro Concealer, Chestnut

- Luigi Table Lamp Soho Home

- Resorts Near Bentonville Arkansas

- Sofa With Secret Compartment

- Mountain Warehouse Snow Boots

- Compost Accelerator Near Netherlands

- Hilton Molino Stucky Venice Shuttle Boat Schedule

- Geneva Airport Taxi Transfers

- Embroidered Medusa Slippers

- Long Sleeve Lace White Dress

- Pacific Coliseum Parking Cost

- Golf Camp For Kids Near New York, Ny

- Lazy Spa Replacement Parts