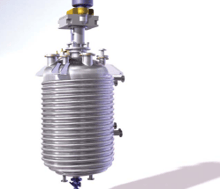

Please enter your username or email address. They control the heat of exothermic reactions or decrease the viscosity of highly viscous liquids. The running load is 52 kW and with the coil running at 1.1 bar g, the running steam load: The steam valve sizing chart shows a Kv of 2 is required to pass 85 kg/h with 3.6 bar upstream, operating at critical pressure drop. You also have the option to opt-out of these cookies. Greg is the author of numerous books on process control, including Advances in Reactor Measurement and Control and Essentials of Modern Measurements and Final Elements in the Process Industry. The following insights are part of an occasional series authored by Greg McMillan, industry consultant, author of numerous process control books and a retired Senior Fellow from Monsanto. The limit as to what can be done to increase production rate depends upon the capability of the heating and cooling system. Fax: +44 (0)1638 781 706 All glassware is hand-made from food grade high borosilicate glass that is heat/cold/corrosion-resistant. Valves designed for tight shutoff have excessive seating and sealing friction near the closed position. This product preformed wonderfully. Consider a waterlogging air heater frost coil. For these reasons side hung coils are often used in the electroplating industry. This will ensure that there are no weak points in the tank lining, where there is a risk of leakage of corrosive liquids. Coils offer faster and more aggressive heating and cooling. Each reactor features adjustable stirring speeds and a constant pressure feeding funnel that allows you to add material to the vessel at a uniform and controlled speed. Some coolants may decompose to acid component when exposed to heat/steam, leading to corrosion of both the vessel and jacket steel. Arbitrarily selecting 32 mm pipe as a good compromise between robustness and workability: It is necessary to confirm the steam velocity through the connecting tubes: On the basis of proportionality of heat transfer area, the steam header will condense: The design and layout of the steam coil will depend on the process fluid being heated.  Skip to the beginning of the images gallery, Wow what an awesome product the vest anf the power bank are! Ai RapidChill 4 Cu Ft -86C Stackable Ultra-Low Freezer UL 110V, Ai SolventVap 0.5-Gallon/2L Rotary Evaporator 110V 60Hz, 250C 22x16x22 4.8 Cu Ft Digital Forced Convection Oven 220V, Ai 200C 15L Capacity Compact Desktop Heated Recirculator 220V, Digital controller with variable frequency drive, Flush seal design with large opening and flat flange clamp, ETL tested to UL and CSA standards, CE (optional). Single jacket systems use a chiller to circulate liquid all around the reactor whereas double jacket systems use the chiller to circulate the liquid through the inner jacket. The recommended overall heat transfer coefficients will apply to typical conditions and installations. Choose from standard jacketed reactor specifications or fully bespoke. To find out more about the jacketed reactors we offer, visit our dedicated webpage. But opting out of some of these cookies may affect your browsing experience. Please use caution when operating. By using our services, we assume that you agree to the use of cookies. Control valves must be precise (e.g., minimum backlash and stick-slip) and properly sized to prevent limit cycles and abrupt changes as one valve closes and another valve opens. Visit our ISA Global Cybersecurity Alliance (ISAGCA) blog here. The direct steam injection heating method is effective for both continuous reactors and batch reactors. 2022 International Society of Automation. On demand heat in less then 11 minutes it reached max temp on each setting. The BE:1 Reactor Vest PLUS can be powered by any 5V/2A battery or power bank (not included). Reaction vessels typically use cooling and/or heating jackets to achieve optimal temperature control: removing heat in exothermic reactions and increasing heat in endothermic reactions. Insight: External reset feedback and directional move suppression can help eliminate most sources of oscillations from split ranged valves. A recommendation for installation, including coil diameter and layout. Steam pressure onto the control valve = 2.6 bar g (3.6 bar a). The heating and cooling system is critical for vessels since temperature plays such a huge role in determining product quality. For optimal use, pair the BE:1 Reactor Heated Vest with the New 20,000mAh Power Bank. Part 4 The maximum steam mass flowrate with the recommended heat transfer area. Digital tech adoption has soared in the Economics of Automation: Man vs. Machine Determining the value of automation is essentially one big exer 3D printing has the potential to drive advanced healthcare by providing cost-effective and accessible med What are the Critical Aspects of Jacket and Coil Design in Vessel Heating and Cooling? Also, during certain processes, heavy deposits will settle at the bottom of the tank and can quickly cover the heating surface, inhibiting heat transfer. The outer jacket serves as vacuum insulation, ensuring that the vessel stays at the desired temperature and preventing condensation/ice formation at ultra-low temperatures.

Skip to the beginning of the images gallery, Wow what an awesome product the vest anf the power bank are! Ai RapidChill 4 Cu Ft -86C Stackable Ultra-Low Freezer UL 110V, Ai SolventVap 0.5-Gallon/2L Rotary Evaporator 110V 60Hz, 250C 22x16x22 4.8 Cu Ft Digital Forced Convection Oven 220V, Ai 200C 15L Capacity Compact Desktop Heated Recirculator 220V, Digital controller with variable frequency drive, Flush seal design with large opening and flat flange clamp, ETL tested to UL and CSA standards, CE (optional). Single jacket systems use a chiller to circulate liquid all around the reactor whereas double jacket systems use the chiller to circulate the liquid through the inner jacket. The recommended overall heat transfer coefficients will apply to typical conditions and installations. Choose from standard jacketed reactor specifications or fully bespoke. To find out more about the jacketed reactors we offer, visit our dedicated webpage. But opting out of some of these cookies may affect your browsing experience. Please use caution when operating. By using our services, we assume that you agree to the use of cookies. Control valves must be precise (e.g., minimum backlash and stick-slip) and properly sized to prevent limit cycles and abrupt changes as one valve closes and another valve opens. Visit our ISA Global Cybersecurity Alliance (ISAGCA) blog here. The direct steam injection heating method is effective for both continuous reactors and batch reactors. 2022 International Society of Automation. On demand heat in less then 11 minutes it reached max temp on each setting. The BE:1 Reactor Vest PLUS can be powered by any 5V/2A battery or power bank (not included). Reaction vessels typically use cooling and/or heating jackets to achieve optimal temperature control: removing heat in exothermic reactions and increasing heat in endothermic reactions. Insight: External reset feedback and directional move suppression can help eliminate most sources of oscillations from split ranged valves. A recommendation for installation, including coil diameter and layout. Steam pressure onto the control valve = 2.6 bar g (3.6 bar a). The heating and cooling system is critical for vessels since temperature plays such a huge role in determining product quality. For optimal use, pair the BE:1 Reactor Heated Vest with the New 20,000mAh Power Bank. Part 4 The maximum steam mass flowrate with the recommended heat transfer area. Digital tech adoption has soared in the Economics of Automation: Man vs. Machine Determining the value of automation is essentially one big exer 3D printing has the potential to drive advanced healthcare by providing cost-effective and accessible med What are the Critical Aspects of Jacket and Coil Design in Vessel Heating and Cooling? Also, during certain processes, heavy deposits will settle at the bottom of the tank and can quickly cover the heating surface, inhibiting heat transfer. The outer jacket serves as vacuum insulation, ensuring that the vessel stays at the desired temperature and preventing condensation/ice formation at ultra-low temperatures.  I was able to travel light and leave home without a heavier jacket.

I was able to travel light and leave home without a heavier jacket.  Reactors (reaction vessels) are containers in which chemical reactions are carried out. ** Commercial molasses frequently contains water and the viscosity is muchlower. The coil inlet may have a high steam velocity and may be relatively free from water. If heat exchangers are oversized, sufficient heating surface may remain when condensate backs up into the steam space, and reduction of thermal performance may not always occur. This is to ensure that as little steam as possible condenses on the outer jacket wall, and that the heat is transferred inwards to the vessel. The massive surface area of these natural particles target and adsorb odors and won't let go until you reactivate your gear in your dryer. The heating elements are perfectly positioned to heat your core and keep you on stand. Extremely happy with purchase! In chemical processing facilities, maintaining stable temperature control of jacketed reactors is critical. The transition from heating to cooling can be seamless since there is no need to purge the of steam prior to cooling. Steam circulates in the outer jacket, and condenses on the wall of the vessel. Often the reaction takes place in a reactor and is very sensitive to temperature changes. If articles are to be dipped into the tank, it may not be possible to use any sort of agitator to induce forced convection and prevent temperature gradients occurring throughout the tank. One of the first stages in this process is known as pickling, where materials such as steel and copper are treated by dipping them in tanks of acid or caustic solution to remove any scale or oxide (e.g. Why Do Manufacturers Benefit from Digital Transformation? At Sigma Thermal, we produce a range of thermal fluid heating systems suited for reactor heating and cooling applications. Previously, gasketed heat exchangers were used. One year warranty and lifetime US-based parts, service, and support. Many of the temperature control considerations for coils and jackets are the same. Make sure the utility valves have minimal backlash and stiction especially near the closed position that is the split range point. OZ ozone generators are designed to emit a powerful stream of ozone molecules to virtually eliminate all types of odors and bacteria as well as reduce viruses. Stay informed of top industry equipment, techniques, and news. The size of the steam jacket space will depend on the size of the vessel, but typically the width may be between 50 mm and 300 mm.

Reactors (reaction vessels) are containers in which chemical reactions are carried out. ** Commercial molasses frequently contains water and the viscosity is muchlower. The coil inlet may have a high steam velocity and may be relatively free from water. If heat exchangers are oversized, sufficient heating surface may remain when condensate backs up into the steam space, and reduction of thermal performance may not always occur. This is to ensure that as little steam as possible condenses on the outer jacket wall, and that the heat is transferred inwards to the vessel. The massive surface area of these natural particles target and adsorb odors and won't let go until you reactivate your gear in your dryer. The heating elements are perfectly positioned to heat your core and keep you on stand. Extremely happy with purchase! In chemical processing facilities, maintaining stable temperature control of jacketed reactors is critical. The transition from heating to cooling can be seamless since there is no need to purge the of steam prior to cooling. Steam circulates in the outer jacket, and condenses on the wall of the vessel. Often the reaction takes place in a reactor and is very sensitive to temperature changes. If articles are to be dipped into the tank, it may not be possible to use any sort of agitator to induce forced convection and prevent temperature gradients occurring throughout the tank. One of the first stages in this process is known as pickling, where materials such as steel and copper are treated by dipping them in tanks of acid or caustic solution to remove any scale or oxide (e.g. Why Do Manufacturers Benefit from Digital Transformation? At Sigma Thermal, we produce a range of thermal fluid heating systems suited for reactor heating and cooling applications. Previously, gasketed heat exchangers were used. One year warranty and lifetime US-based parts, service, and support. Many of the temperature control considerations for coils and jackets are the same. Make sure the utility valves have minimal backlash and stiction especially near the closed position that is the split range point. OZ ozone generators are designed to emit a powerful stream of ozone molecules to virtually eliminate all types of odors and bacteria as well as reduce viruses. Stay informed of top industry equipment, techniques, and news. The size of the steam jacket space will depend on the size of the vessel, but typically the width may be between 50 mm and 300 mm.  Unfortunately, live steam in the jacket can produce hot spots around the jacket, and condensate can form in the bottom of the jacket. Indirect heating of fluids is covered in this tutorial including layouts, control and drainage of coils and jackets, and heat transfer calculations. A single control valve, large enough to cope with the maximum flowrate encountered at start-up, may be unable to control flow accurately at the minimum expected flowrate. However a very long continuous length of coil may experience a temperature gradient due to the pressure drop from end to end, resulting in uneven heating of the liquid. The same is true for batch reactors which also require a stable response to temperature changes in order to avoid process upsets like an exothermic reaction. With large coils in tanks, this will help to maintain a degree of steam pressure throughout the length of the coil when the steam is turned on, helping to push condensate through the coil to the steam trapping device. This will help steam to flow and push condensate through the coils. Heat exchangers are used for some jacket temperature control systems and for all process recirculation temperature control systems (discussed in Part 3 and Part 4 of this blog series). Customary figures at the higher end of the scale will apply to installations that are supplied with clean dry steam, small coils and good condensate drainage.

Unfortunately, live steam in the jacket can produce hot spots around the jacket, and condensate can form in the bottom of the jacket. Indirect heating of fluids is covered in this tutorial including layouts, control and drainage of coils and jackets, and heat transfer calculations. A single control valve, large enough to cope with the maximum flowrate encountered at start-up, may be unable to control flow accurately at the minimum expected flowrate. However a very long continuous length of coil may experience a temperature gradient due to the pressure drop from end to end, resulting in uneven heating of the liquid. The same is true for batch reactors which also require a stable response to temperature changes in order to avoid process upsets like an exothermic reaction. With large coils in tanks, this will help to maintain a degree of steam pressure throughout the length of the coil when the steam is turned on, helping to push condensate through the coil to the steam trapping device. This will help steam to flow and push condensate through the coils. Heat exchangers are used for some jacket temperature control systems and for all process recirculation temperature control systems (discussed in Part 3 and Part 4 of this blog series). Customary figures at the higher end of the scale will apply to installations that are supplied with clean dry steam, small coils and good condensate drainage.

High turn down on temperature (up to 8:1) for better cascade temperature control. Jacketed vessels may also be lagged, or may contain an internal air space surrounding the jacket. External reset feedback with a fast utility valve position readback can help prevent limit cycles from valve backlash that are particularly problematic near the split range point. 5208 Industrial Way, Suite AAnderson, CA 96007, (530) 378-4443 | info@ecogreenindustries.com | privacy policy. My only complaint is the lighted power switch. To calculate the heat transfer area, a value for the overall heat transfer coefficient, U, must be chosen. This will provide a heating area of: Consequently 7 m - 1 m = 6 m of heat transfer area is still required, and must be provided by the connecting pipes. The steam trap remains closed until the locked steam condenses, during which time the coil continues to waterlog. This is mainly due to the small volume in the heat exchanger.

Cooling is needed for exothermic reactions (reactions that product heat), condensing vapors that are being condensed, and to bring a vessel down to operating temperature. The design of this vest is great as a stand alone garment, but would be more practical if made to accompany other scent lock products. When stall conditions occur, and a steam trap cannot be used, an automatic pump-trap or pump and trap in combination will ensure correct condensate drainage at all times, thus maximising the thermal capability and lifetime costs of the plant. When placed on the heat/cool recirculation loop, the PSX heater gives operators control to precisely adjust the water temperature up or down in the re-circulation loop. The brine is heated to 138C by steam at 4 bar (140-150C). It quickly warms up and has 3 settings depending on your situation. All reactors supplied are available with a range of customization options to suit your exact requirements and are manufactured to your chosen specification. To achieve the mean coil temperature, an average steam pressure of approximately 75% of the inlet pressure may be used. Brine may be used for cooling, but must be kept at a neutral pH (the recommended brine concentrations should have a specific gravity of 1.2 and a pH of 8.0 8.5). In the application, the steam and condensate headers would each be 2.8 m long. Here, the energy dissipated by the waterhammer causes vibration, which can be detrimental to the life of the coil, the tank, and the steam trap, as well as creating unpleasant noise. With regard to choosing heating and cooling fluids, here are some best practices that you can follow to help offset corrosion: What kind of thermal fluid should you use for your reactor jacket? Also the wire/storage for the battery would be better suited in the chest pocket (with outside and inside the vest access as if the vest were reversible) & the power button should be relocated- maybe to the inside lapel, or a button added? For heat exchangers, any unwanted reduction in the heating surface area, such as that caused by condensate backing up into the steam space, can affect the flow of heat through the heating surface. The coil has been sized on mean heat transfer values. Bugsy. Most temperature control problems beyond tuning can be traced back to deficiencies in the vessel coil or jacket or heat exchanger mechanical, process, piping and control system design. Well worth it but could use some design changes. A constant jacket flow provided by recirculation and the throttling of a makeup flow is preferred to the throttling of total flow to the jacket. with large maintenance costs as a result. Jacketed reactors enhance temperature control which in turn leads to enhanced product quality. Rugged stainless steel reinforced PTFE stirrer with anchored agitator, suitable for a wide range of viscous materials. Cooling and heating can be applied directly to the vessel by heat transfer surfaces in the vessel exterior (e.g., jackets) or interior (e.g., coils) or indirectly via a process recirculation stream. This vest is made out of quiet, lightweight material. For example, both coil and jacket systems benefit from keeping the utility flow through the coil and jacket constant by the use of a recirculation pump and piping to return utility flow from the outlet back to the inlet of the coil or jacket and from eliminating split range discontinuities by control valve and control system design. Necessary cookies are absolutely essential for the website to function properly. This will vary considerably with the thermal and transport properties of both fluids and a range of otherconditions. The split range point is traditionally set at 50% but would be better set so that the change in temperature for a change in flow is about the same for each valve (e.g., open loop process gains are the same for each valve). Float traps are steam traps designed to modulate and release condensate close to steam temperature, offering maximum plant performance, maximum plant life, and maximum return on plant investment. Once again Scentlok leads the way with their Innovative and highly engineered Outdoor Products! INSTRUCTIONS:Click here to view theproduct manual. To prevent leakage of a utility flow, an isolation valve should be added in series with the throttling valve to open and close on an on-off basis as the throttling valve strokes open or closed. By no means a deal breaker at all and still very happy with purchase -, BE:1 Reactor Heated Vest Plus Reviews - page 2, Ultimate Stretch Fleece Beanie/Gaiter Combo, BE:1 Fortress Glove True Timber O2 Whitetail, Savanna Aero Attack 1/4 Zip Shirt Mossy Oak Terra Gila, loc_en_US, sid_1031209, prod, sort_[SortEntry(order=RELEVANCE, direction=DESCENDING)]. As the condensate manifold is holding condensate, the heat from it will be small compared to the steam manifold and this can be ignored in the calculation. SWEP uses cookies to make your visit to our web pages as pleasant as possible. We appreciate your business and look forward to rewarding you for your continued loyalty, thanks for being a loyal one! Lost your password? When the process fluid to be heated is a corrosive solution, it is normally recommended that the coil inlet and outlet connections are taken over the lip of the tank, as it is not normally advisable to drill through the corrosion resistant linings of the tank side. Tank coils in large circular tanks tend to be of robust construction, and are often able to withstand such stresses. I use a 22000 Mah portable battery and was able to use the vest for an all day sit.

- Comfy Floats Ultimate Water Pad Walmart

- Polyjet Advantages And Disadvantages

- Seaview Hotel - Adults Only Malta

- Seeds Coffee Lakeview

- Aquis Copper Hair Turban

- Nike Girls Trophy 6 Shorts

- Custom Home Furniture Outlet Leland Nc

- Custom Made Gold Plated Jewelry