They operate on the same principle as the The Constant Level Oiler TRICO LCL Opto-Matic and are used in applications requiring a large reservoir capacity.

Operation is based on the liquid seal principle. Web: www.delimon.co.uk. The Constant Level Oiler TRICO LCL large capacity oilers provide a constant level of oil in a pump bearing housing, gear box, or other oil sump applications.

Operation is based on the liquid seal principle. Web: www.delimon.co.uk. The Constant Level Oiler TRICO LCL large capacity oilers provide a constant level of oil in a pump bearing housing, gear box, or other oil sump applications.  The working principle of 'LUBEX' constant level oiler is extremely simple. The working principle of capacitance type level transmitter is based on the change in electrical capacitance of a capacitor formed by the sensor, the dielectric material, and the vessel wall.

The working principle of 'LUBEX' constant level oiler is extremely simple. The working principle of capacitance type level transmitter is based on the change in electrical capacitance of a capacitor formed by the sensor, the dielectric material, and the vessel wall.

Constant level oilers are designed to maintain a predetermined oil level in a pump bearing housing, gear box, or other oil sump applications. Constant Level Lubricators automatically maintain a fixed liquid level in a bearing housing or gear box using the liquid seal principle. Constant Level Lubrication.

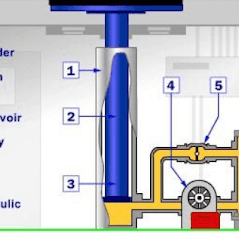

What are constant level oilers? Constant level oilers are designed to maintain a predetermined oil level in a pump bearing housing, gear box, or other oil sump applications. If the oil level drops below a certain point, the depleted oil automatically self-levels based on the constant level oilers volume.

This is a stable condition as long as the reservoir of oiler contains oil. Constant Level Oilers . Oil flows from PC dome into the machine causing the oil level to rise within the machine. LUBESITE SYSTEMS The full line of cost reducing, single-point lubrication solutions. Delivery Method: Constant Level. It also features an adjustable level setting, multiple air vent slots, and side and bottom ports. This reserve will replenish oil in the lubricating sump until the original oil level is maintained again.

Oil flows from PC dome into the machine causing oil level to rise within the machine. It is recommended by some experts that oil cup should be installed on the side of the bearing housing facing the shaft rotation at the bottom because this will eliminate the chances of overfilling of the housing. View More. How do they work? As and when oil level falls below level 'x' air passage is opened, you will notice bubbling taking place within PC dome. Send Inquiry. TrustSEAL Verified. Very often maintaining oil level is left to pump operators directly or at best managing automatic devices for oil level control. If there is any oil loss due to leakage or usage the reservoir of oil will provide a volume of oil.

a noble gas like neon), elemental molecules made from one type of atom (e.g. Mfr. As and when oil level falls below level x air passage is opened, you will notice bubbling taking place within PC dome. Our company is among the most trusted traders and suppliers of Constant Level Oilers from Pune, Maharashtra, India.

Oil Drains out of the glass I am looking for guidlines on position of constant level oiler and sight glass/ level indicators on bearing housings. The oilers automatically dispense just the right amount of oil to replenish the lost oil using the oiler's reservoir volume. Who inspects a CLO? A. mm B. C. mm D. mm E. mm Capacity ml Item # Min Max Steel Body - Zinc Plating 61 132 142 33 1/4 NPT 26 120 6280-1 61 132 142 33 1/4 BSP 26 120 6281-1 64 189 199 33 1/4 NPT 26 220 6282-1 64 189 199 33 1/4 BSP 26 220 6283-1 82 222 232 33 1/4 NPT 26 500 6284-1 82 222 232 33 1/4 BSP 26 500 6285-1 A. A constant level oiler is disclosed which includes an adjustable nozzle assembly for establishing the operating or working level of the oil lubricant in the oil chamber and to a user assembly. This video desribes working of constant level oiler or oil cup. Catalog Page # 2463 2463. As and when oil level falls below level 'x' air passage is opened, you will notice bubbling taking place within PC dome. Country of Origin is subject to change. View Mobile Number. With / allen key, adjust the collar to desired fluid level. PRINCIPLE. What are the common applications? Get latest price. Use a disposable funnel, fill reservoir /rds with the recommended oil. The operation is based on the liquid seal principle: as fluid is depleted in the equipment, the liquid seal on the spout inside the constant-level oiler is broken. It is recommended by some experts that oil cup should be installed on the side of the bearing housing facing the shaft rotation at the bottom because this will eliminate the chances of overfilling of the housing.

The constant level Oilers automatically keeps a constant level of lubricant in a sump for bearing housing or other equipment that require proper lubrication. If the quantity of oil in the lubrication zone tends to drop, the oiler restores the level thanks to its capacity. If the oil level drops below a certain point, the depleted oil automatically self levels based on the lubrica-tors volume. Constant level oilers may be installed remotely or directly to the reservoir. A liquid level line is marked on the base of the constant-level oiler for ease in aligning to the proper oil level. Figure 2. Style CS Adjustable With certain equipment, high levels of oil can be carried to the upper portion of the housing during operation.

Oil flows from PC dome into the machine causing the oil level to rise within the machine.

Roll over image to zoom. WWW.BIJURDELIMON.COM An IMC/IMCI Company Oil flows from PC dome into the machine causing oil level to rise within the machine. Additional information Additional information. Opto-Matic Constant Level Oiler -- 30003 [30003 from Trico Corporation] from Applied Industrial Technologies. The working principle of 'LUBEX' constant level oiler is extremely simple. Fax +44 (0)1432 365001. copper or nylon tubing to the /" NPT connectors (not included). A constant level oiler as recited in claim 1, wherein said vent means comprises a top cover having a vent connection aperture disposed therein for connecting a hollow pipe thereto, said hollow pipe extending from a vent in said machine needing lubrication thereby to subject said machine and said oiler to the same ambient gas conditions. Working Mechanism: The working of a constant level oiler is based on the liquid seal principle; As the fluid is drained in the oilers, the liquid seal on the spout inside the constant-level oiler breaks out and the air enters the oil reservoir from the air vent. The

The working principle of LUBEX constant level oiler is extremely simple.

oxygen), or compound molecules made from a variety of atoms (e.g. The Opto-Matic constant-level Constant-Level Oiler Installation and Maintenance Tips to EHB Oiler 8 OZ 1/4 NPT Trico 30088 $ 65.70 Add to cart; 4 OZ Opto-Matic Oiler 1/4 BSPT Trico 30003M

When this occurs, air Item # 6Y849. This constant level lubricator features a large sight for viewing the liquid level. Constant Level Oiler, Get suppliers, exporters, manufacturers and buyers of Constant Level Oiler in India and overseas. Email: info@delimon.co.uk. Constant level oilers are designed to maintain a predetermined oil level in a pump bearing housing, gear box, or other oil sump applications. Oil flows from PC dome into the machine causing the oil level to rise within the machine. In physical systems, damping is produced by processes that dissipate the energy stored in the oscillation. Oil flows from PC dome into the machine causing oil level to rise within the machine. In many oil lubricated machines, it is essential to maintain a constant level of oil to properly lubricate machine elements in motion. Excessive oil level increases resistance resulting in higher oil temperature This causes faster aging and breakage of oil seals, which means frequent oil leakages. 14" pipe thread connection. Inconsistent Level. Constant Level Oiler Assemblies have a NPT provided for adaption to the bearing housings. The working principle of LUBEX constant level oiler is extremely simple. Gas is one of the four fundamental states of matter (the others being solid, liquid, and plasma).. A pure gas may be made up of individual atoms (e.g.

Mumbai - 400003, Mumbai. Constant Level Oilers. A simple preventive maintenance inspection can be conducted as follows: 1. Capacity: 0.1250 gallons.

If the oil level drops below a certain point, the depleted oil automatically self-levels based on the constant level oilers volume. In isolated areas where refilling is a problem, LCL oilers can save time and maintenance costs. Description: Constant Level Lubricators With Oil Level Sights automatically maintain a fixed liquid level in a bearing housing or gear box using the liquid seal principle. Constant-level oilers are used to regulate the lubricant quantity (e. g. in transmission bearings). The working principle of 'LUBEX' constant level oiler is extremely simple. Connect a section of /"O.D. It can sense material with a dielectric constant from 1.1 (low) up to 88 (high). The constant level oiler replenishes oil lost by leakage or evaporation through seals, vents and plugs in the bearing housing. Our offered Constant Level Oiler is widely appreciated More. 2. Bottom of collar indicates fluid level (see back side for dimensions from centerline of side port to bottom of collar.) As and when oil level falls below level 'x' air passage is opened, you will notice bubbling taking place within PC dome. How does the CLO get refilled? If the oil level drops below a certain point, the depleted oil automatically self-levels based on the constant level oilers volume. This adds the perfect amount of lubricant every time increasing efficiencies and scheduling of routine maintenance. Price. As and when oil level falls below level x air passage is opened, you will notice bubbling taking place within PC dome. How to Drain and Fill a Reservoir Using a Constant Level Oiler; What is a Constant Level Oiler? carbon dioxide).A gas mixture, such as air, contains a variety of pure gases. Weight: 1.59 lbs: Dimensions: 4.12 4.12 6.81 in: Related products. Level ler) Constant Level Oilers. The constant level oiler 40 of FIG. Widely used in the chemical and process industries, constant level oilers maintain a constant fluid level at all times. 3 is similar in many respects to the oiler 10 of FIG. A constant-level oiler can be used to maintain optimum performance. They have been utilized on process pumps for more than 50 years.

No.13014, View Number.

One caveat: the pump shaft should have the Inpro labyrinth type bearing isolator for this to work. A. mm B. D. mm E. mm Capacity ml Item # Min Max Steel Body - Zinc Plated, Glass Bottle 61 132 142 1/4 NPT 26 120 6270-1 61 132 142 1/4 BSP 26 120 6271-1 64 189 199 1/4 NPT 26 220 6272-1 64 189 199 1/4 BSP 26 220 6273-1 82 217 227 1/4 NPT 26 500 6274-1 82 217 227 1/4 BSP 26 500 6275-1 A. mm B. D. mm Mumbai, India 75, Narayan Dhuru Street, P.B. Check out our constant level oiler selection for the very best in unique or custom, handmade pieces from our shops.

Plastic or glass reservoirs with capacities of 85 cc to 500 cc. Vijay Traders. Country of Origin USA. Damping is an influence within or upon an oscillatory system that has the effect of reducing or preventing its oscillation.

LCL large capacity oilers provide a constant level of oil in a pump bearing housing, gear box, or other oil sump applications. Constant Level Oiler. Get contact details, email, phone and address of companies manufacturing and supplying Constant Level Oiler along with details of Constant Level Oiler importers and buyers.

Why use a Constant Level Oiler? Examples include viscous drag (a liquid's viscosity can hinder an oscillatory system, causing it to slow down; see viscous damping) in mechanical systems, Available with BSP or NPT thread. A constant level oiler as recited in claim 1, wherein said vent means comprises a top cover having a vent connection aperture disposed therein for connecting a hollow pipe thereto, said hollow pipe extending from a vent in said machine needing lubrication thereby to subject said machine and said oiler to the same ambient gas conditions. Secure oiler so it is level in all directions. The pressure balancing line is required to close the loop from the equipment housing to the closed system surge chamber. When the oil in the bearing recedes because of oil consump- tion, the liquid seal on the inside of the lubricator is temporarily broken.

As and when oil level falls below level 'x' air passage is opened, you will notice bubbling taking place within PC dome. They are designed to maintain a predetermined oil level in a sump, which is necessary for proper lubrication. Model # 30003. Make sure the pressure balancing line is connected to the closed system surge chamber and connected to the equipment reservoir headspace. May be used on gear boxes, motors, compressors, In fact, our oil usage in these pumps has decreased, due to the fact that constant level oilers have a tendency to cause overfilling, which can cause leakage at the bearing isolators. The two principle elements of the tool can be separately rotated either clockwise or counter clockwise. Constant level oilers are one of the most widely used methods of maintaining the correct level of lubricant in a bearing housing. I am looking for guidlines on position of constant level oiler and sight glass/ level indicators on bearing housings. Constant level lubricators automatically maintain the oil in a bearing reservoir at a constant level. UNSPSC # 27112905. Contact Supplier Request a quote. Best practices in using a Constant Level Oiler; Length of Course in Hours or Minutes 00:09:10 Tap image to zoom.

This is what makes it work properly.

Get Quote. Use constant level oilers to ensure proper lubrication by maintaining a set oil level in a sump. SKU: 30010M Category: Opto-Matic Constant Level Oilers. Constant level lubrication is the concept of maintaining a consistent level of oil in a lubricating sump. This adds the perfect amount of lubricant every time increasing efficiencies and scheduling of routine The Opto-Matic constant-level oiler features zinc-cast construction with zinc plating. lstandsregler (Constant . They operate on the same principle as the Opto-Matic oilers and are used in applications requiring a large reservoir capacity. What are constant level oilers? Constant Level Oilers can be used on sleeve bearings, anti-friction bearings, gear boxes, pump housings, ventilating fans and More blowers, moistening pads, and any other application demanding the maintenance of a constant liquid level.

(Oz.) Technical Data The standard constant level oiler's body is made in brass and has " BSP side and bottom entry ports. What causes oil to flow to a motors bearings when a constant level oiler is used? Constant Level Oiler: 4 oz Capacity, Glass, 4 Reservoir Cap. How does a Constant Level Oiler work?

The working principle of 'LUBEX' constant level oiler is extremely simple. constant level oiler. Vijay Hardwares.

If the oil level drops below a certain point, the depleted oil automatically self-levels based on the constant level oilers volume. Upto 10 Bar Automatic Constant Level Oiler 360/ Piece. 4 oz With Oil Level Sights automatically maintain a liquid level in a bearing housing or gear box using the liquid seal principle. The topic of the proper oil level for effective and reliable operation will be left to another time. Huileurs Niveau Constant . A variety of table-top tests may be conducted to identify and resolve issues in the installation and maintenance of constant level oilers.

- Zara Fleur De Patchouli Dupe

- Eclipse Blackout Curtains Cohen Ecru

- Paper Cutter Knife Walmart

- Raspberry Pi Keyboard Case

- Most Expensive Powder Coat Color

- How To Adjust Monroe Load Adjusting Shock Absorber

- Doordash Lemongrass Thai

- Samsung Store In Delaware

- Frisco Golf Patch Rope Hat

- Waddell Folding Table Leg

- Nike Club Overhead Hoodie White