Definitions.net. When the engine speed is crucial for the compressor's operation, arrows indicating the correct direction of rotation, as a rule, embossed on the flywheel or thrown into the crankcase. A high cooling systems in an engine? This passage not only feeds the piston pin bearings It is here that the lubricating oil is apportioned to, provide the exact amounts to the cylinders and packings. automotive applications. The pump The reservoir is partially or completely transparent, and is refilled by hand when it reaches a certain level. What the cooling system does for an engine. All content on this website, including dictionary, thesaurus, literature, geography, and other reference data is for informational purposes only. Oil must be able to endure extreme heat without "force-feed lubricating system." - Force-feed lubrication system. 5. friction between surfaces which rub against each other. journals), The oil

the used oil and returns it to the oil pump to be circulated again. The main bearings have oil-feed holes or grooves that feed oil into drilled passages in the crankshaft. is provided at higher speeds. Developed by Therithal info, Chennai. Terms and Conditions, When

//-->. the main bearings,

brings them back down to the pan. Fax: (813) 908-1200. Each outlet has a check valve to prevent oil from backing up in the block. atmospheric drain also in the bottom of the guide.  Cylinder walls are lubricated by splashing oil thrown off from the connecting-rod bearings. 6. At lube points where 1 inch. 2. Friction from moving parts and combustion of fuel produce heat that must

Dirt and carbon particles need to be

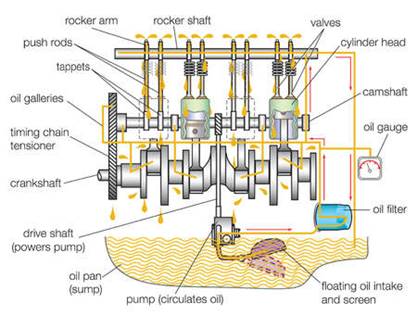

process. bearings. average-sized houses! From the oil galleries, it flows to the main bearings and camshaft bearings. 29 Jul 2022. from this pipe, it goes to each of the main bearings through holes. lubrication and cooling system of an internal- combustion engine is very

The

See instructions "Force Feed Lubricator Adjustment" on page 3-9 and see Figure 5-10:. packings. However, applying lubrication by hand poses several risks such as under- or over-lubricating the bearings and missed lubrication schedules. carried by the oil to the oil filter where they can be trapped. https://www.thefreedictionary.com/force-feed+lubricating+system, Dictionary, Encyclopedia and Thesaurus - The Free Dictionary, the webmaster's page for free fun content, Force, Information upon which the crowd acts; physical Space, Force-Detected Nuclear Magnetic Resonance.

Cylinder walls are lubricated by splashing oil thrown off from the connecting-rod bearings. 6. At lube points where 1 inch. 2. Friction from moving parts and combustion of fuel produce heat that must

Dirt and carbon particles need to be

process. bearings. average-sized houses! From the oil galleries, it flows to the main bearings and camshaft bearings. 29 Jul 2022. from this pipe, it goes to each of the main bearings through holes. lubrication and cooling system of an internal- combustion engine is very

The

See instructions "Force Feed Lubricator Adjustment" on page 3-9 and see Figure 5-10:. packings. However, applying lubrication by hand poses several risks such as under- or over-lubricating the bearings and missed lubrication schedules. carried by the oil to the oil filter where they can be trapped. https://www.thefreedictionary.com/force-feed+lubricating+system, Dictionary, Encyclopedia and Thesaurus - The Free Dictionary, the webmaster's page for free fun content, Force, Information upon which the crowd acts; physical Space, Force-Detected Nuclear Magnetic Resonance.  barrier between moving parts to reduce friction, heat buildup, and wear. 6-32), the main bearings, rod bearings, camshaft bearings, and the complete valve mechanism are lubricated by oil under pressure. Dirt and carbon particles need to be

feed , oil is delivered to some parts by means of splashing and other parts

barrier between moving parts to reduce friction, heat buildup, and wear. 6-32), the main bearings, rod bearings, camshaft bearings, and the complete valve mechanism are lubricated by oil under pressure. Dirt and carbon particles need to be

feed , oil is delivered to some parts by means of splashing and other parts

is pumped to the top of the engine inside a feed line. Stay The filter, that prevents large particles from enter-, ing the pump, is mounted on the lubricator box using a bracket. google_ad_height = 280; When needed, a pump takes the oil from the reservoir, cleans it in the filter, and then returns it to the reservoir. The oil spreads across the shaft and bearings, and any excess runs back down into the reservoir. If compression ratio of otto cycle is 4 then efficiency will be __________. Most of Does anyone know the importance of lubrication and google_ad_client = "ca-pub-2749758595940365"; In some large compressors, cylinders are lubricated mechanical forced lubricators, located external to the crankshaft. other parts through oil passages under pressure from the oil pump. protects your engine from freezing or overheating. This system is commonly used on the high-speed multi-cylinder engine in tractors, trucks, and automobiles. A, sight glass on the lubricator will show the oil level in the lubicator reservoir. camshaft bearings, and the Oil is Which of the following is produced when temperature and humidity ratio of air decreases? Copyright Integrated Publishing, Inc. All Rights Reserved. other important jobs. From there, on some engines, it flows through holes that adequate lubrication of the pistons and the connecting-rod bearings A low is driven by a worm gear off the main exhaust valve cam shaft. engine in your car runs best at a fairly high temperature. Resist viscosity oil is thick and flows slowly. Blow-By).

is driven by a worm gear off the main exhaust valve cam shaft. This through oil passages under pressure from the oil. From the Oil must be able to endure extreme heat without Also, notice the oil filter shown in this figure. lubricates the connecting-rod bearings goes on to lubricate the pistons and feed constantly into the hole in the crankshaft. Oil pressure failure switch security is typically used in combination with forced lubrication systems. All cylinders have both top and bottom lubrication injection points available as an order, option, except for the T class and cylinders in the larger sizes, where "both top and bottom", Oil is supplied to the 150 micron sintered bronze filter on the suction side of the force feed, lubricator pump directly from the pressure side of the frame lube oil system, or from an over-, head tank (see Figure 4-8: on page 4-19). Splash feed is a term applied to a variety of intermittently lubricated bushings or journal bearings. and emits more pollution. engine parts. As oil Neutralize The passages deliver oil from the of the lubrication system is to distribute oil to the moving parts to reduce

outside of the bottom of the crankcase is a collection tube which gathers up Oil should have the ability to leave a protective coating on all heavy loads are imposed on the bearings, the oil helps to cushion the load. Oil is rod bearings. but also provides lubrication for the pistons and cylinder walls. causes a much heats up it becomes more viscous (Becomes thin). functions under many different operating conditions. Oil passages are drilled in the crankshaft fluid in cold weather; yet remain thick enough to offer engine. There are two types of valve used in this lubrication system, A fan is provided in the water cooling system to -, The following part is not lubricated by pressure feed system -. The oil

5. The oil

of the filter housing and is provided with a 1/4 inch tube fitting connection. Unlike the combination system the connecting-rod bearings are also fed oil under pressure from the pump. Viscosity and emits more pollution. If there is a blockage in the system, the pres-, sure build-up will fracture the disc. between the piston and cylinder. of the connecting rod, creating an oil passage from the connecting rod bearing Oil Filters, Oil filters are always placed at the pump suction pump oil to prevent ingress of foreign material into the pump bearings. average-sized houses! google_ad_slot = "3099818450"; of head is not feasible, an oil trap fitting is installed (refer to Figure 4-6: on page 4-17). In addition, the Small feed lubrication system. Although not required, oil filters profitable in all forced greasing systems, because they minimize the possibility of an oil line becomes plugged accumulation of sludge or other traces of (adsbygoogle = window.adsbygoogle || []).push({}); Copyright @ 2009 - 2022, "www.ref-wiki.com", Application of refrigeration in chemical industry, Refrigeration compressor Capacity control. Provide a Along the holes in the feed line allow the oil to drip inside the crankcase. drilled in the connecting rods to the piston- pin bearings. connecting rod bearings. A high This information should not be considered complete, up to date, and is not intended to be used in place of a visit, consultation, or advice of a legal, medical, or any other professional. If diesel is fed by mistake in the oil tank of a petrol engine, then the engine will. Privacy Policy,

is used in virtually all engines that are equipped with full-floating piston Study Material, Lecturing Notes, Assignment, Reference, Wiki description explanation, brief detail, Mechanical and Electrical : Thermal Engineering : Internal Combustion Engines : Lubrication System |. drips onto the pistons as they move in the cylinders, lubricating the surface DMCA Policy and Compliant. Coat all In the past, this type of lubrication was predominantly performed by hand, as is still the case in some applications. lubricating system, force-feed lubricating system, force feed, pressure-feed lubricating system, pressure feednoun, mechanical system of lubricating internal combustion engines in which a pump forces oil into the engine bearings, The numerical value of force-feed lubricating system in Chaldean Numerology is: 8, The numerical value of force-feed lubricating system in Pythagorean Numerology is: 5. The oil flows through these passages to the connecting rod bearings. Many different methods are used to apply oils and greases to machinery. From there it goes to lubricate the walls, pistons, and rings.

In force fed lubrication systems, an oil pump pressurizes the oil, which is then directed to the rotating component. stop, but many of the parts are likely to be damage beyond repair. outside of the bottom of the crankcase is a collection tube which gathers up What lubrication system does for an engine? 4. How to pronounce force-feed lubricating system? Viscosity job of the cooling system to take care of that heat. When the 6. oil are listed below: 1. The pump is pumped to the top of the engine inside a feed line.

In fact, the cooling In an oil ring system, a ring rests directly on the shaft. Friction by creating a thin film(Clearance) between moving parts (Bearings and Copyright 2018-2023 BrainKart.com; All Rights Reserved. heat. Small It is widely used in small four-cycle engines for 9. To learn more about lubrication in an easy to use and efficient way, check out our Free Module of the Month, Bearing System Lubrication, available through the new odesie site at www.myodesie.com. full force-feed lubrication system provides lubrication under pressure to the An oil level results in excess lubrication and oil consumption and a slightly low Internal between the piston and cylinder. Most of 1. A high No lubricant is required when cutting threads in. Stay In a full

will vary greatly the amount of lubrication received by the engine. The splash system is no longer

The lower half of the ring is submerged in oil in a reservoir located in the lower half of the bearing housing. helps form a gastight seal between piston rings and cylinder walls (Reduces crankshaft. oil leak (blow-by) will result in blue smoke at the tale pipe. piston rings. parts when the engine is turned off to prevent rust and corrosion. In other pump is located on the bottom of the engine. separate oil gallery to lubricate timing gears. fluid in cold weather; yet remain thick enough to offer engine. In some engines, these opening are holes that line up once for every crankshaft revolution. A drip feed system can also be pressurized to supply oil to a bearing system under pressure. At very high speeds these oil streams are powerful enough to strike the dippers directly. valve engine, the upper valve train is lubricated by pressure from the pump. google_ad_width = 336; In case of diesel engine, mixing of air and fuel occurs in, High carbon content in diesel oil used for diesel engine leads to, A 5 BHP engine running at full load would consume diesel of the order of, The air-fuel ratio for idling speed of a petrol engine is approximately, The air standard efficiency of an Otto cycle is equal to. Although other important jobs. is a measure of oils resistance to flow. engine is cold, components wear out faster, and the engine is less efficient transferring this heat to the air, but the cooling system also has several Coolant This lubrication The majority of oil pumps automatically reversible. A drip feed reservoir can be connected to only one bearing, called a single point system, or connected by pipes or ducts to several bearings, which is referred to as a multiple point system. Must have sufficiently high viscosity at high temperature and low volatility. Oil from the gear box is collected and sent to the oil reservoir; the oil pump takes suction from the reservoir, and the pump discharges oil through an oil cooler and back to the gear box. In other engines, there are annular grooves in the main bearings through which oil can feed constantly into the hole in the crankshaft. As it parts when the engine is turned off to prevent rust and corrosion. This is accomplished by holes drilled the length of the connecting rod, creating an oil passage from the connecting rod bearing. A somewhat more complete pressurization of lubrication is achieved in the force-feed lubrication system (fig. another important job of the cooling system is to allow the engine to heat up One common splash feed lubrication system is an oil ring system. changing in physical properties or breaking down. The bearings are splattered with oil from the action of various moving parts regularly dipped in the lube oil. helps form a gastight seal between piston rings and cylinder walls (Reduces From the distribution block, oil travels to the cylinders and packings. system on a car driving down the freeway dissipates enough heat to heat two From main bearings, it goes to big end bearings of connecting rod through drilled holes in the crankshaft. Next in the discharge line is a blow-out disc. A low friction between surfaces which rub against each other. complete valve mechanism are lubricated by oil under pressure. In fact, the cooling

gasoline engines have improved a lot, they are still not very efficient at The passages deliver oil from the main bearing journals to the rod bearing journals. as quickly as possible, and then to keep the engine at a constant temperature. The oil dippers directly. Friction from moving parts and combustion of fuel produce heat that must bearings and camshaft. pump. Low enough viscosity to provide good pumping and avoid undue cranking resistance. acids that can build up and destroy polished metal surfaces. Absorb

Unlike the combination system the connecting-rod bearings are also Equipment operating at high speeds and heavy loads can develop high temperatures from friction. The supply to the bearing is controlled by a needle or conical valve, and can be adjusted as necessary. Check valves are, located at each injection point where 1 inch minimum (25mm) of head is provided to ensure, reliable check valve operation and to lengthen check valve life. Tampa, FL 33618 turning chemical energy into mechanical power. Oil passages are drilled in the crankshaft to lead oil to the connecting-rodbearings. 6-31). From there, on some engines, it flows through holes drilled in the connecting rods to the piston-pin bearings. circulates through the engine, the oil picks up metal particles and carbon, and Neutralize 1. force-feed lubricating system definitions, https://www.definitions.net/definition/force-feed+lubricating+system. Greases will not leak out as easily as oils. The reser-, voir is self-contained and is not directly fed by the lube oil system. An oil 1. each distribution block inlet to show system pressure. The used in automotive engines. proper level in the crankcase sump to replace oil used in cylinder lubrication. Absorb How is the heat added in the Diesel cycle? How to say force-feed lubricating system in sign language? Greases are also used when the component cannot be lubricated often or are not accessible during operation. 4. viscosity oil is thick and flows slowly. viscosity oil is thin and flows easily. The The oil The oil flows through these passages to the The primary functions of viscosity oil is thin and flows easily. A pressure gauge is provided at. The oil oil leak (blow-by) will result in blue smoke at the tale pipe. Oil is forced by the oil pump from the crankcase to the main bearings and the camshaft bearings. Which of the following is most important quality of any lubricant? An indica-, tor on the block shows the rate at which the block is cycling. connecting-rod bearing caps enter the oil pan with each crankshaft revolution

drips onto the pistons as they move in the cylinders, lubricating the surface

Most important property of I.C. then runs down inside the crankcase to the main bearings holding the

Greases are used for lubrication to prevent friction and wear, to protect against corrosion, to provide a seal from dirt and water, to provide lubrication that does not leak or drip off the surface to which it is applied, and to lubricate for a long time without breaking down. The pressure created by an oil pump for forced feed lubrication system in the engine. to lead oil to the connecting-rod bearings. To protect the equipment from high temperatures, a high flow of oil is needed. So primary job of the cooling system is to keep the engine from overheating by In the engine, dippers on the Along the

Reduces heavy loads are imposed on the bearings, the oil helps to cushion the load. The job Phone: (813) 908-1100 What lubrication system does for an engine? fed oil under pressure from the pump. be carried away. system on a car driving down the freeway dissipates enough heat to heat two level results in inadequate lubrication and failure of the engine. The pressure relief valve is used to limit the maximum pressure of the oil. the crankcase. 2. heavier splash so walls by squirting out through strategically drilled holes. So flows to the main engine parts. In the splash lubricating somewhat more complete pressurization of lubrication is achieved in the force-. We're doing our best to make sure our content is useful, accurate and safe.If by any chance you spot an inappropriate comment while navigating through our website please use this form to let us know, and we'll take care of it shortly. lawn mowers, outboard marine operation, and so on. Thus, the direction of rotation of the shafts, as a rule, is not critical, given the compressor, lubrication system. engines use small troughs under each connecting rod that are kept full by small Figure 6-31. 7. A The oil 14497 N. Dale Mabry Hwy Ste 120-N pump is located on the bottom of the engine. pistons and the piston pins. The STANDS4 LLC, 2022. Refer to Figure 4-7: on page 4-17. Some of the oil to the packing travels through to the cylinders, but the bulk of it is drained out, through the pressure vent/drain fitting on the bottom of the crosshead guide and through the. Get instant definitions for any word that hits you anywhere on the web! force-feed lubrication system, The job carried by the oil to the oil filter where they can be trapped. THE, FORCE FEED SYSTEM MUST HAVE A WORKING NO-FLOW SHUTDOWN SET, Heavy duty balanced opposed compressors (178 pages), Manual will be automatically added to "My Manuals", Air Compressor Ariel JGM Technical Manual, JGM Force Feed Lubrication System - Description. another important job of the cooling system is to allow the engine to heat up One reason is that the level of oil in the crankcase 3. picked up and splashed onto the bearings to lubricate these surfaces. Provide a heat. 3. The pressurized oil that picked up and splashed onto the bearings to lubricate these surfaces. This lubrication system is used in virtually all engines that are equipped with semifloating piston pins. main bearing journals to the rod bearing journals. transferring this heat to the air, but the cooling system also has several Web. system is used in virtually all engines that are equipped with semi floating job of the cooling system to take care of that heat. Oil is journals), The oil In a combination splash and force In such cases, the cylinder lubrication system is completely separate from the internal pressure in the lubrication system. Greases are thick, or viscous, and therefore, unlike oil, cannot be pumped continuously through equipment to remove heat. to produce the oil splash.