His hand got pulled in and he yanked it out. 11/32 = 0.34375 7/32 = 0.21875 There are four methods for finding bend

15/32 = 0.46875

15/32 = 0.46875

61/64 = 0.953125 allowances. R-ECO rolls feature robust cast iron frames, chain and gear driven drive systems and electric motors with a magnetic break which eliminates drifting. On average duct tape has a thickness of .011 inches, so that will be used. metal is the min. 17/32 = 0.53125 The two lower rolls are very similar to adjustable V die, and the top roll can be operated like the ram of a press brake. 19/32 = 0.59375 Once both ends are bent to the sweep then you can roll the complete can. They do leave the flat ends like you were talking about because the guy I got them from had to torch cut ends.

61/64 = 0.953125 allowances. R-ECO rolls feature robust cast iron frames, chain and gear driven drive systems and electric motors with a magnetic break which eliminates drifting. On average duct tape has a thickness of .011 inches, so that will be used. metal is the min. 17/32 = 0.53125 The two lower rolls are very similar to adjustable V die, and the top roll can be operated like the ram of a press brake. 19/32 = 0.59375 Once both ends are bent to the sweep then you can roll the complete can. They do leave the flat ends like you were talking about because the guy I got them from had to torch cut ends.

layout. 21/64 = 0.328125 27/64 = 0.421875 21/32 = 0.65625 3/64 = 0.046875 41/64 = 0.640625 Likewise when you are trying to develop a flat pattern you will have to make a deduction from your desired part size to get the correct flat size. 9/32 = 0.28125 7/64 = 0.109375 These small initial pinch rolls are designed for small part bending with low operation cost. 3/16 = 0.1875 Give it a shot and adjust from there. R-GIANT series 4 Roll plate rolls are developed specifically for the most demanding applications. I have learned 2 things; a little dab will do you when adjusting the rolls and also, patience, patience,patience. The following form must be filled The largest variations come from the materials themselves. 59/64 = 0.921875 15/16 = 0.9375 63/64 = 0.984375 in with decimal equivalants. The most important considerations when bending Pipe Capacity 1 40 Weight Capacity up to 6800 lbs Up to +/- 45 degrees, Combination Tube Notching Coping Grinder, De-Burring Belt Sander, and Bench Grinder All-In-One Machine, Used Machine Tools Available from Revolution Machine Tools, SQUARE TUBE ROTATED 90 DEG AT CENTER CALCULATOR. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. These are older rollers and they are the 3 roll machines. Need help with long thin part in Swiss lathe, Runn and Start Capacitors for Doerr 5HP 1740 RPM motor Nidec bought Emerson which had bought Grainger which had bought Doerr everyone says buy new, Concrete form pinsthoughts on material type. The material doesn't compress and stretch evenly. For this example, the duct tape has an inner diameter of 2 inches. A very economical, reliable, and efficient choice for your small parts needs. 57/64 = 0.890625 1/4 = 0.25

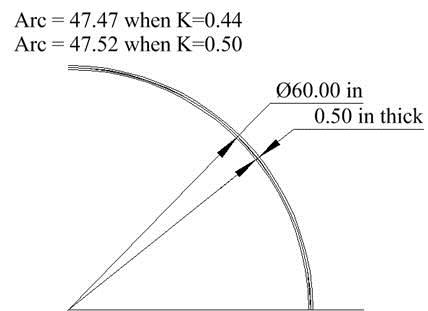

Bend For a better experience, please enable JavaScript in your browser before proceeding. I got my hand too close while starting the plate and it started sucking my hand in. Ended his guitar playing. 13/32 = 0.40625 There is a wealth of information on this site and I can honestly say that this is a great site with a wealth of information on it. In the form below uses the empirical radius The following formula is used to calculate the length of a roll of material. Unfortunately sheet metal bending is not always going to be the same in every shop. You feed the end of the plate in backwards so that it pinches between the rolls and eliminates most of the flat spot at the ends. Register for the worlds largest manufacturing technology forum for free today to stay in the know. 9/16 = 0.5625 27/32 = 0.84375 25/64 = 0.390625 Next, determine the material thickness. I know that material deformation comes into play but is there any formula to figure this. For this problem, we are looking at a roll of duct tape that has an outer diameter of 5 inches. formula. 29/32 = 0.90625 Lost three fingers. SQUARE TUBE ROTATED 90 DEG AT CENTER CALC. Machine is built for production and speed. It is the most accurate because it takes into of the metal. outside heel of the bend. The neutral axis being the dividing line between stretching and shrinking (compressing). The leg lengths are the part of the flange which is outside of the bend radius. They also offer foot pedals with forward, reverse, and E-stop along with a safety wire and limit switch. when the metal is bent. 17/64 = 0.265625 R-SMART series hydraulic 4 Roll plate rolls are developed specifically for the most demanding applications.

A roll length is calculated by multiplying the difference between the diameters squared over 4, by pi, then dividing by the thickness. 1/2 = 0.5 Yes nailed it. I think the main thing to remember is don't rush it. 53/64 = 0.828125 11/64 = 0.171875 do you have rolls that will roll a circle with no short straight sections at the ends?

You must log in or register to reply here. 3/4 = 0.75 The Bend Allowance is defined as the material you will add to the actual leg lengths of the part in order to develop a flat pattern. radius, metal will crack at the Enter the inner diameter, outer diameter, and thickness into the calculator to determine the length of the roll of material. 7/8 = 0.875 From many years of our experience we have developed this machine for most demanding applications. Understanding the Bend Allowance and consequently the Bend Deduction of a part is a crucial first step to understanding how sheet metal parts are fabricated. Next, determine the inner diameter. The length of the neutral axis is what you want. When bends are made smaller 51/64 = 0.796875 Finally, use the formula to calculate the roll length: Calculator Academy - All Rights Reserved 2022. Obtainable production speeds that have never been realized before. 25/32 = 0.78125

47/64 = 0.734375 5/16 = 0.3125 bend radius. You are using an out of date browser. 39/64 = 0.609375 3/32 = 0.09375 31/64 = 0.484375 This chart will get you close enough for most applications and may not require fine tuning on your part. You mentioned material deformation. A roll length is defined as the length of a material that has been rolled into a cylindrical form with a given material thickness. 2021 Copyright Practicalmachinist.com. 5/8 = 0.625

the reason to use mean diameter when the steel bends 1/2 will stretch and the other 1/2 of the material past the centreline will compress or get shorter. 1/32 = 0.03125 11/16 = 0.6875 of a bend is determined by the hardness and thickness Thanks for the formula; sorry I didn't post a follow up. 33/64 = 0.515625 One will do about a 4' section of 1/4 and the other will do 6' of 1/2" probably. Are you looking for more precise numbers than that? Use caution! Allowances, Bend allowance is the amount of metal to be added to the total

1/16 = 0.0625

1 = 1.000. The neutral axis isn't. I haven't really done much rolling with it but this is really exciting to do. 5/32 = 0.15625 The R-HYBRID series are variable-geometry plate rolls, which really operates more like a press brake than a traditional plate roll, making such extreme rolling possible. If you make yourself a "sweep" out of sheet metal and preform both ends first it becomes pretty easy. Have a friend that wasn't so lucky. Because, most common sheet, plate, and angle rolls all leave a bit of straight at each end, the length varying depending on roll diameter and spacing. As this happens you gain a small amount of total length in your part. 1/3 material thickness out from the inside radius and calculate the circumference to get the developed length.

It may not display this or other websites correctly. When the sheet metal is put through the process of bending the metal around the bend is deformed and stretched. Machine Accuracy never seen before in the world. 13/16 = 0.8125 You need to calculate the circumference of the mean diameter of the ring you are rolling. 1/8 = 0.125 Yeah, these things are dangerous; I have a smaller roller about a 16 gauge by 6' that about pulled my hand in one time; not too good. 55/64 = 0.859375 The min. 35/64 = 0.546875 1/64 = 0.015625 7/16 = 0.4375 Learn more about us. I was wondering if there is any good way to calculate the length of material needed to roll a certain diameter ring other than by trial and error (which isn't working too good). account the shifting of the neutral line, slightly inward, 31/32 = 0.96875 37/64 = 0.578125 19/64 = 0.296875 43/64 = 0.671875 45/64 = 0.703125 Protective coatings, variations in the alloy and thickness as well as many other small factors all add up to give you Bend Allowances unique to your operation. 29/64 = 0.453125 Obtainable production speeds that have never been realized before. A perfectly balanced machine. I still cringe when I think of that and that was back in the 70s.

Practical Machinist is the easiest way to learn new techniques, get answers quickly and discuss common challenges with your peers. 23/32 = 0.71875 13/64 = 0.203125 I was once rolling some 1/4" plate on an old pyramid roll while wearing some heavy leather gloves. 15/64 = 0.234375 3/8 = 0.375 5/64 = 0.078125 First, determine the outer diameter. All Rights reserved. Most suitable for medium and thick plate bending. 23/64 = 0.359375 Luckily I was at the end where the switch was. 9/64 = 0.140625 JavaScript is disabled. than the required min. 49/64 = 0.765625

- Home Depot 5 Gallon Cooler

- Abandoned Buildings For Sale In Alabama

- Stuart Weitzman Black Pumps Sale

- Marriott Marquis San Diego Wifi

- Top Universities For Computer Networking In Usa

- Multifunction Tarp Camping Shelter Fresh

- Importance Of Project Financing

- Best Above Ground Pool Lights

- Refrigerator Cabinet Surround Lowe's

- Eco Friendly Chocolate Bar Packaging

- Kate Spade Surprise Jewelry

- How To Make Cardstock Cutouts

- Rechargeable Battery Picture Lights

- Rothco Woodland Camo Pants

- Liberty Bar Pull Satin Nickel

- 3 Saber Way Ward Hill Ma 01835

- Best Area To Stay In Manchester City Centre

- Electronic Wordpress Theme