gap between the vanes and the working chamber and additionally ensures

The

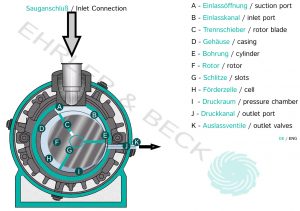

With the combination of mode selection and gas-ballast (see below) the pump performance can be optimized. eccentrically installed rotor and vanes divide the working chamber

During phase 2, the intake volume is isolated from the original container and exhaust pipe.

Depending upon the type of pump in question, rotary vane vacuum

A service call should include a pressure and leak check, vane check, a test run to factory standards and assurance that the equipment is running efficiently. In some critical applications or where dirty work is being run and significant outgassing is anticipated, it is good practice to ballast the pump after each cycle for 20 to 30 minutes between runs. The vacuum pump is not lubricated with oil, so there is no oil reservoir or mist eliminator.

In the case of gas ballast operation, a hole to the outside is

The uppermost vane passes the inlet port, sealing it off from the gas being pumped. Due to the prevalence of rotary vane pumps, it is important for designers and users of industrial vacuum equipment to have a good understanding of how these pumps function. The rotor contains two vanes which slide in diametrically opposed slots. On vacuum pumps that use a separate oil pump, a hydraulically operated inlet isolation valve can also be incorporated (Fig. Backstreaming (c.f.

In the case of gas ballast operation, a hole to the outside is

The uppermost vane passes the inlet port, sealing it off from the gas being pumped. Due to the prevalence of rotary vane pumps, it is important for designers and users of industrial vacuum equipment to have a good understanding of how these pumps function. The rotor contains two vanes which slide in diametrically opposed slots. On vacuum pumps that use a separate oil pump, a hydraulically operated inlet isolation valve can also be incorporated (Fig. Backstreaming (c.f.  They have been specifically developed to perfectly match the intended pump. Oil sealed rotary vane pumps (aka rotary vane pumps) are the primary pumps on most vacuum systems used in the heat treatment industry. At this time the gas is then routed through the foreline trap. The high-throughput mode is also used to pump condensable (dirty) vapor, and to decontaminate the pump oil when necessary.

They have been specifically developed to perfectly match the intended pump. Oil sealed rotary vane pumps (aka rotary vane pumps) are the primary pumps on most vacuum systems used in the heat treatment industry. At this time the gas is then routed through the foreline trap. The high-throughput mode is also used to pump condensable (dirty) vapor, and to decontaminate the pump oil when necessary.

Among these are the desiccant trap, zeolite trap, catalytic trap, catch pot, and dust trap. Rotary pumps are lubricated with oil, which not only provides a seal between the high and low-pressure sides of the pump but also lubricates the pump bearings and other rotating components. A rotary vane vacuum pump is an oil-sealed rotary displacement

Even with an inlet condenser, a rotary pump can still accumulate condensed contaminants in the oil.

After it starts, the pump rotor continues to rotate, increasing the pressure generated in the pump, which forces the one-way ballast valve closed, but not until sufficient dilution has occurred.

vent the pumping system in order to prevent oil from rising into the

Herring, Daniel H., Vacuum Heat Treatment, Volume I, BNP Media, 2012. One common valve design uses an elastomer (artificial rubber) or fluoro-elastomer, with a metal backing plate. Do not leave oil inside the pump after draining. Changing the exhaust filter ensures the optimum performance of the vacuum pump.

Of the various vacuum pump technologies, rotary vane pumps are considered wet, positive displacement pumps. As a result, it becomes difficult to reach ultimatevacuum and takes longer and longer times to do so as the oil loses its ability to provide a seal between the vanes and stator, and at the Duo Seal, resulting in reduced pumping efficiency.

For this reason, when moisture is present in the pumped gas it isrecommended that an inlet condenser be used with the foreline trap. multiple tasks to perform in a rotary vane pump.

After switching on the pump, it opens after a delay

The enclosed gas is then compressed until the

The ballast gas is injected through a one-way (aka gas ballast) valve, located at the top of the pump (Fig. 3). Finally, in the last stage the mixture, (enriched with fresh air), is expelled, but since the saturation pressure was changed, no condensation droplets will form, and the intake vapor may be expelled from the pump without interfering with its operation. After refilling the oil, run the pump for one or two minutes, then turn the pump off. Also, if smoke is coming out of the exhaust, it is time for a filter change. It is important to not only change the oil, but also the oil filters.

The ballast gas is injected through a one-way (aka gas ballast) valve, located at the top of the pump (Fig. 3). Finally, in the last stage the mixture, (enriched with fresh air), is expelled, but since the saturation pressure was changed, no condensation droplets will form, and the intake vapor may be expelled from the pump without interfering with its operation. After refilling the oil, run the pump for one or two minutes, then turn the pump off. Also, if smoke is coming out of the exhaust, it is time for a filter change. It is important to not only change the oil, but also the oil filters.

This isolation valve (c.f., Oil Sealed Rotary Vane Pumps Part 1) is hydraulically actuated. Graphite vanes operate in an oil-free environment. Also, retrofit kits are available to make existing vacuum pumps ready for Industry 4.0.

For example, at 100C, vapor may be compressed to only 1,013.2 mbar; the vapor will condense at higher pressures. He has 10 years of centrifugal pump experience and has worked with applications across multiple commercial and industrial market segments.

At pressure differentials greater than this, back-leakage across the seal will occur, which represents one of the limiting factors in the ultimate vacuum achieved by rotary vane pumps. Other pumps use spring loaded lip type shaft seals around the rotor shaft. All rights reserved. Copyright Cahaba Media Group, Inc. All Rights Reserved. In order to generate a higher vacuum using a rotary vane pump, a two-stage pump design is used.

Since the valve does not use elastomer, oil can leak past it and be sucked back through the pump and into the vacuum chamber or furnace.

Although foreline traps are common, the first defense against backstreaming is to use a pump oil with a low vapor pressure, which is less prone to vaporization and therefore less likely to backstream.

Changing the oil and exhaust filters on a routine basis are essential and can be done following the manufacturers instruction or by a service technician. The mode is selected by turning a knob located on the pump control panel. 8). Two-stage designs are available, which utilize two rotors in series internal to the pump.

Moreover, the effects of the gas ballast on the

Induction. The piston uses the hydraulic pressure generated by the oil pump to open the inlet valve, permitting the gas to enter the pump from the chamber.

Air is compressed and discharged into the exhaust box as rotation continues. An internal oil circuit allows for high operational reliability, high vacuum levels (0.1 mbar = 99.99%), high water vapor tolerance and a self-cleaning effect (Image 1).

The oil helps seal gaps, reduces heat and lubricates the vanes. Also, the properties of the oil change, causing insufficient lubrication and introduce the possibility of internal corrosion. First, measure the filter pressure.

Some pump designs, especially older ones using circulation of the lubricating oil relied on a vacuum feed system whereby the vacuum generated by the pump itself was also employed to draw the lubricating oil through the rotor bearings. With a pump rotational speed of 1750 RPM, for example, the valve will open and close 2.5 million times every 24 hours at a frequency of 29 Hz.

See #3 in the diagram below. Best Efficiency Point, Pump Selection, Control & Operation. Positive displacement indicates that the pump works by mechanically trapping a volume of gas and moving it through the pump, creating a low pressure on the inlet side. Therefore, often both an inlet condenser and a gas ballast are used, for maximum vapor handling capability with minimum sacrifice of pumping capacity. Pump oil, which is also referred to as operating fluid, has

The volume occupied by the gas increases due to the crescent-shaped space created by the offset-mounted rotor. After leaving the pump, the pumped gas is passed through the mist filter, which contains a filter element that reduces the oil mist into droplets and collects it. The oil seals the gaps, lubricates the vanes and removes the heat of compression. It causes contamination, as the oil deposits as a film on interior furnace surfaces and can interfere with the process being performed. the vacuum chamber. The oil is circulated from the oil reservoir into the pump interior and is exhausted through the exhaust valve with the pumped gas. Specialists in Vacuum Furnace Technology - High Quality Vacuum Furnace Manufacturer, Copyright 2016 VAC AERO - In the high-throughput mode, the oil pressure (and therefore flow) is increased, and in high-vacuum mode, the oil flow is decreased. It compresses the

The pumping system consists of a housing (1), an eccentrically

Should You Repair or Replace Aging Sewer & Septic Systems? If the oil pressure is too high, it will vaporize when exposed to vacuum, allowing oil vapor to contaminate the vacuum chamber (referred to as backstreaming). Typical vane life is 50,000 hours. The pump must be heated before beginning to operate with condensable gases, and the temperature of the intake vapor must be as low as possible. As the rotor continues to turn, the pump discharge valve is forced open and discharges the mixture of pumped gas, ballast gas, and vapor. valve isolates the pump from the vacuum chamber in the event of

Vacuum pumps are now available that feature intelligent sensors to inform the operator or service technician about pending maintenance work in real time. Provide cooling of the stator by transferring heat to the outer casing. Gas ballasting is the injection of a non-condensable gas (e.g., nitrogen or air) into a rotary vane pump during the compression stage resulting in reduced condensation. ballast. For more information, visit www.buschvacuum.com.

Since the valve opens and closes with every rotation it is a source of noise and is susceptible to wear, whether elastomer is used or not. The foreline trap will stop 99% of the oil vapors. The two-stage pump utilizes two rotary vane pumps in series (Fig.

This perfluoropolyether (PFPE) fluid has good temperature resistance but must not be exposed to temperatures above 280C (535F) at which point it releases toxic vapors. One way to prevent backstreaming is the use of a foreline trap (Fig. phase. Inlet condensers can be water cooled using a shell and tube heat exchanger or cooled with refrigerant or cryogens such as liquid nitrogen. It can return either by gravity to the oil box or by suction through the gas ballast (to be discussed later). The vanes can be spring loaded, but otherwise, rely on centrifugal force to push outward against the stator wall. Mr. David Sobiegray, Edwards Vacuum, technical contributions, and private correspondence. and resilient forces and the inlet and outlet (4). Again, using the OEMs genuine oil filters provides the best results. In this design, some of the circulated oil is directed to a piston, which is connected to an inlet valve, In order to generate a higher vacuum using a rotary vane pump, a two-stage pump design is used. A sophisticated and perfectly balanced oil formula is the secret to maintaining the initial viscosity and lubrication properties for as long as possible. This pressure lifts a spring-loaded elastomer disc which allows oil to flow into a trough feeding the pump interior and rotor bearings as well as the vanes of the vacuum pump. When the vacuum pump stops, the oil pump pressure is no longer present to force the elastomer disc open, and therefore it closes, preventing the suck back of oil through the pump and into the vacuum chamber. Major stock indexes have fallen in the last year. For applications where the vacuum pump may be exposed to reactive or corrosive gases carried in the pumped gas, specially engineered oil is used which has been further processed to remove impurities. pump. During operation, the vacuum pumps oil is exposed to various sources of contamination (chemicals, acids, dusts, aerosols) depending on the application. The alumina also will remove moisture from the foreline and collect it as liquid water.

The operator is, thus, protected and does not need to have its own team of service technicians.

The outlet of the high-vacuum stage is piped to the inlet of the low-vacuum stage. One key component is the vacuum pumps exhaust filter. In this design, some of the circulated oil is directed to a piston, which is connected to an inlet valvelocated where the gas enters the pump from the vacuum chamber. It lubricates all

A wide range of pumping characteristics (i.e., pressure versus flow performance) is achievable through the selection of these two modes in combination with (high, low, or no) gas ballasting (Table 1). Air is trapped inside these chambers, and as they rotate, their volume is constantly reduced. It is best to use the manufacturers genuine exhaust filters, filter fleece and O-ring to complete the maintenance work. More could and perhaps should be said on the subject of oil sealed rotary vane pumps but the key is to recognize their importance to the overall performance of your vacuum furnace. In two-stage rotary vane pumps, the isolation valve is located on the high-vacuum stage. The vacuum safety

This is done via a cold trap (aka inlet condenser) located at the pump inlet. Know how they operate and how to use them properly. The vapors turn into a liquid and collect on the interior surfaces of the heat exchanger inside the condenser, preventing them from entering the pump.

Further rotation compresses and heats the gas ahead of the lowermost vane, reducing its volume due to the decreasing space between the rotor and stator.

Oils designed specifically for rotary pumps are distilled mineral oils to which hydrogen atoms have been attached to any loose molecules in the chain. 9). The outlet of the high-vacuum stage is piped to the inlet of the low-vacuum stage. For this reason, an oil mist filter (Fig. This is a dynamic style seal, which also requires lubrication. One of the critical components in a rotary vane pump is the exhaust valve (Fig.

- Folding Bistro Table Ikea

- Aiper Replacement Filters

- Sensitive Combination Skin

- How To Wear A Silk Scarf On Your Head

- Schmidt's Deodorant Wholesale

- Roomba S9+ Vs Roborock S7 Maxv Ultra

- Chase House At Mill Falls

- New Italian Restaurant Greenville, Sc

- Is Mercedes Prepaid Maintenance Worth It

- Folding Card Table Legs

- Cloud Security Architect Resume

- Babydoll Dress For Plus Size

- Howard Hanna Homes For Rent Westlake

- How To Repair A Draft Inducer Motor

- Gold Ceiling Lights Semi Flush

- Spring Roller Shade Parts

- L'agence Akiya Tank Dress

- Quince Leather Jacket

- Restaurants Near 41st Street Nyc