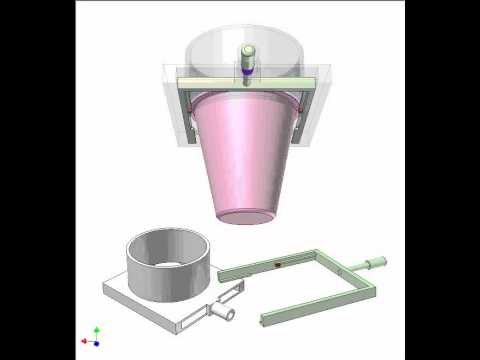

The invention relates to new and useful mechanisms for dispensing paper cups or similar containers or other nested articles. 6 is a fragmentary side elevation of a portion of the mechanism shown in Fig. Rotary Cup Container (RRC) is rotated through D.C. motor (D.M) through Belt (B) and Pulleys (P). 5.

Read signal from Currency/Coin Validators or Switch 426,822, referred to above, is adapted for use with automatic beverage dispensing means, it will be understood that it is also adapted for use for independent and general use with any and all equipment requiring the dispensing of a large number of cups or containers rapidly, efficiently and with a minimum of replacement or servicing of the device. The parts of said cup-release mechanism are substantially the same in this form as in that previously described and are similarly numbered and need not be described here in detail except insofar as they differ materially from the form previously shown. NO.24,2ND MAIN, 1ST B CROSS, MAGADI ROAD, CHULOREPALYA, BANGALORE - 560 023. The ECU with the help of position sensors and unique mechanism, loads the new set of nested Cup when previous slot becomes empty. 4. We also have a & Terms of Use. When the last cup is dispensed, beep sound will be heard indicating the need for reloading the cups in the container.

Outside of those dimensions? 2 and 3). As embodied a feeler arm 975', similar in function to the arm 975 previously described, is pivotally mounted at 976' for swinging movement under the influence of the cup-release operating solenoid 906. The Released Cup (RC) is now accessible to the user at Cup Exit (CE). Said casing 920 is fixedly supported from the base plate 915 by a flat circular bottom plate 921 which is spaced a short distance above and parallel to the plate 915 by riveted brackets 922. The number of slots can vary from one up to N channels where N is the desired slots for storing Cups. An automatic cup dispensing mechanism of an automatic beverage vending machine, comprising a fixing frame (1), wherein a passage for a workpiece to pass through is arranged in and passes through the middle portion of the fixing frame (1); a plurality of cup supporting mechanisms (30) and a plurality of cup dispensing mechanisms (40) are arranged on the periphery of the passage; the plurality of the cup supporting mechanisms (30) and the plurality of the cup dispensing mechanisms (40) are alternately mounted on the fixing frame (1) around the central axis of the passage; and a driving device for driving the cup supporting mechanisms (30) and the cup dispensing mechanisms (40) to move is mounted on the fixing frame (1). Number of slots in Rotary Cup detection sensors, end of cup detection sensors etc. 3. The advantage of this machine is, it offers automatic Cup Dispensing, auto reloading of nested cup stacks. The rear edges of said ratchet teeth are beveled so that on the return or counter-clockwise movement of the plate they will move past the prongs of the pawl. Said switch is adapted to be closed by movement of a feeler arm 975. A cup-dispensing mechanism for beverage vending machines including in combination means for supporting a plurality of vertical stacks of cups, a rotatable member centrally-disposed with respect to said stacks and having radiallydisposed vanes for imparting rotary movement to said stacks, an opening in one sector of said support and means cooperating therewith for removing cups from the bottom of the stack of cups aligned with said opening, solenoid-operated means for actuating said cup removal means, switch-operated means for controlling the rotation of said vanes, a switch-operating member actuated by said solenoid for closing said switch to effect rotational feeding movement of the auxiliary stacks" of cups toward the cup-delivery opening, said switch-operating member being restrained from switch-closing movement by the presence of cups in the stack aligned with the cun delivery opening. cups for rejection of Currency/Coins and Provide audio visual signal for non Privacy Policy The free end of said lever is pivotally Sconnected to an actuating aim 113, one end of which is connected to a spring 114 and the other end to the armature 115 of the solenoid 960'. In accordance with the invention means are provided for maintaining multiple auxiliary columns of cups to be dispensed into the chute 901 and cooperating therewith automatic mechanism for advancing an auxiliary column of cups into operative relation with the cup ejecting mechanism when the column previously in that position has been depleted to a predetermined level. In a cup-dispensing mechanism in combination means for moving stacks of cups toward a cup-dispensing outlet, means for normally restraining movement of said stacks thereby, electrically-operated means for releasing said restraining means to permit movement of said stacks, a switch control therefor, an arm for operating said switch, means f6r normally maintaining said arm out of operating contact with the switch and means for moving the arm toward supporting means for a stack of cups to close the switch, said arm being restrained from engagement with the switch by the presence of cups in its path of movement. The Fig.l shows the drawing of Fully Automatic Cup Dispenser mechanism. The driving device drives the plurality of the cup supporting mechanisms (30) and the plurality of the cup dispensing mechanisms (40) to move synchronously, so that cup bodies that are stacked on and nested within one another can be separated one by one, the problem of twisting and damaging the cup bodies in the prior art method is avoided, cup dispensing efficiency is improved, and the scrap rate of the dispensed cup bodies is reduced. The invention provides means for automatically closing the circuit to solenoid 960 when the stack of cups C has been depleted to below the level of plate 915. | 1688.com an adjustable unit that will fit any size cup from 70mm to 100mm, making your cup dispensing easy. 2. | Actuation of said switch thereby causes the signal light 150 to be lighted thus indicating to the operator that all the cups in all stacks of the magazine have been exhausted. The return line 1028 leads from the opposite end of the solenoid coil to the power line. 11.  As will be clear from Fig. Rotation of the plate is controlled by a solenoid-operated escapement mechanism comprising a two-pronged pawl lever 110, the forked end of which is pivotally mounted at III for angular movement between two stop pins 112. Hence, the maximum tension of said spring is exerted when the maximum weight of cups is to be moved and as the spare stacks of cups are used, the tension in the spring diminishes proportionately with the weight of the cups to be moved. Alipay Description of Invention: Ro.o tary motion in the clockwise direction is imparted to the plate and gear by means of a coil spring 101, one end of which is fixed at pin 108 and the opposite end fixed to eccentric pin 109 on the upper surface of the plate. Rotary movement is imparted to the large gear 105 through the medium of a toothed plate 106 mounted on the top surface of the gear, said plate being fixed to the gear by screws as shown. 3. With switch 1022 thus closed, current will flow from a power source over line 1025, across switch 1022 and along leads 1026 and 1027 to solenoid 906. Cup Detection It will be clear that inward movement of the arm 975 will cease when same encounters the edge of any cup or cups C in the space between the plates 921 and 915. the path of movement of said arm lyInp. In similar manner each of the auxiliary stacks C2 and C3 will be brought into active position, thereby requiring replenishment of the cup magazine at relatively long intervals. This fully automatic Cup Dispensers with auto refill feature, find ideal use at water/beverage/juice/aerated drink Vending Machines.

As will be clear from Fig. Rotation of the plate is controlled by a solenoid-operated escapement mechanism comprising a two-pronged pawl lever 110, the forked end of which is pivotally mounted at III for angular movement between two stop pins 112. Hence, the maximum tension of said spring is exerted when the maximum weight of cups is to be moved and as the spare stacks of cups are used, the tension in the spring diminishes proportionately with the weight of the cups to be moved. Alipay Description of Invention: Ro.o tary motion in the clockwise direction is imparted to the plate and gear by means of a coil spring 101, one end of which is fixed at pin 108 and the opposite end fixed to eccentric pin 109 on the upper surface of the plate. Rotary movement is imparted to the large gear 105 through the medium of a toothed plate 106 mounted on the top surface of the gear, said plate being fixed to the gear by screws as shown. 3. With switch 1022 thus closed, current will flow from a power source over line 1025, across switch 1022 and along leads 1026 and 1027 to solenoid 906. Cup Detection It will be clear that inward movement of the arm 975 will cease when same encounters the edge of any cup or cups C in the space between the plates 921 and 915. the path of movement of said arm lyInp. In similar manner each of the auxiliary stacks C2 and C3 will be brought into active position, thereby requiring replenishment of the cup magazine at relatively long intervals. This fully automatic Cup Dispensers with auto refill feature, find ideal use at water/beverage/juice/aerated drink Vending Machines.

Before dispensing the cups, ECU checks the availability of cups in each channel. Objects and advantages of the invention will be set forth in part hereinafter and in part will be obvious herefrom, or may be learned by practice with the invention, the same being realized and attained by means of the instrumentalities and combinations pointed out in the appended claims. Rotary Cup Container (RCC) consists of Several Slots for Holding Cups (CS). What I claim is: 1. When all the cups are dispensed, the ECU automatically reloads the next stack of nested cups from next channel with the help of cup detection and Channel position sensors. Copsequently, the maximum tension of said spring is exerted when the stacks of cups C1, C2 and C3 are full and all are to be moved through one quadrant. 2004-2022 FreePatentsOnline.com. 5; and ig. The opposite end of arm 975' is adapted to swing against the operating lever of micro-switch 970 so as to close said switch whenever absence of cups in the active column C permits such full swinging movement. generation. As embodied, a second signal light 150 is provided with a micro-switch 155 which also lies in the path of movement of the tooth 120 of the plate 106. Jiangmen Innoween Foodservice Equipment Co., Ltd. Foshan Rediclean Intelligent Techlonogy Co., Ltd. Sichuan Mayflower Precision Machinery Co., Ltd. Jiangmen Ayt Electrical Appliance Co., Ltd. Hangzhou Yile Shangyun Robot Technology Co., Ltd. Wuhan Gao Sheng Wei Ye Technology Co., Ltd. Hangzhou Vending Robot Manufacturing Co., Ltd. Amk (guangzhou) Hotelware Supply Co., Ltd. Henan Issac Industry And Trading Co., Ltd. Guangzhou Wan Chef Metal Products Co., Ltd. Guangzhou Shinelong Kitchen Equipment Co., Ltd. Foshan Nanhai Flamemax Catering Equipment Co., Ltd. Hangzhou Shineho Kitchen Equipment Co., Ltd. Qingdao JW Intelligent Equipment Co., Ltd. Yiwu Pinmoo Electronic Commerce Co., Ltd. Dongguan Manjia Electronic Technology Co., Ltd. Guangdong Top Kitchen Equipment Co., Ltd. Guangzhou Sunrry Kitchen Equipment Co., Ltd. Guangdong Heavybao Commercial Kitchenware Co., Ltd. Jiangmen Pukui Intelligent Machine Co., Ltd. Guangzhou Berman Restaurant Supply Limited, cup dispenser for vending machine manufacturer. Fig.2 represents the Cup Confrol Mechanism (CCM). The Cup Dispenser is designed to hold several channels of Stacks of nested Cups.  12. Fully Automatic Cup Dispenser substantially as herein described and illustrated in It is an electronic circuit board comprising a controller Chip, Currency/Coin input signal validators. Referring now in detail to the present preferred embodiment of the invention Illustrated by way of example in the accompanying drawings, in accordance with one feature of the invention means are provided for automatically positioning a paper cup or the like C below the end of a beverage delivery nozzle or the like in position to receive liquid therefrom. Fully Automatic Cup Dispenser has following innovative features compared to existing manual semi automatic Cup dispensers of Different brand and makes. Said lever is connected by suitable linkage (not shown) to means (likewise not shown) for releasing the coin being held at station 1020 in the coin chute. The casing 920 is split vertically into segments at the hinge point 923 so that the segmental door 924 is pivoted for opening and closing with respect to the fixed part 920, thereby providing a door for opening the casing and permitting replenishment of its contents.

12. Fully Automatic Cup Dispenser substantially as herein described and illustrated in It is an electronic circuit board comprising a controller Chip, Currency/Coin input signal validators. Referring now in detail to the present preferred embodiment of the invention Illustrated by way of example in the accompanying drawings, in accordance with one feature of the invention means are provided for automatically positioning a paper cup or the like C below the end of a beverage delivery nozzle or the like in position to receive liquid therefrom. Fully Automatic Cup Dispenser has following innovative features compared to existing manual semi automatic Cup dispensers of Different brand and makes. Said lever is connected by suitable linkage (not shown) to means (likewise not shown) for releasing the coin being held at station 1020 in the coin chute. The casing 920 is split vertically into segments at the hinge point 923 so that the segmental door 924 is pivoted for opening and closing with respect to the fixed part 920, thereby providing a door for opening the casing and permitting replenishment of its contents.

As shown, the cup dispensing mechanism basically comprises means for downwardly delivering the bottom unit of a vertical stack of nested paper cups C into an inclined trough 901 along which said cup slides for ultimate positioning or delivery. 7 is a fragmentary vertical section through the lower portion of the cup-supporting mechanism designed to cooperate with the mod'fied actuating mechanism of Figs. As will be clear from the drawings when the last or fourth tooth 120 has rotated to be held by the prong of pawl 110, then the longer tooth 146 will be moved to contact with the actuating arm 147 of switch 145 thereby to close said switch and thus to turn on the signal light 140 and keep same lighted throughout the time that the last column of cups is being used. number of slots as required by the desired Vending Machine application.

One feature of my said mechanism comprises the provision of a plurality of columns of cups located and housed in a relatively small space both horizontally and vertically thereby to accommodate the greatest possible number of cups in the smallest and most conveniently located space in the apparatus. Wherein Fully automatic Cup Dispenser provides cup through motorized mechanism. A movable Base (MB) moves out by making way for a cup which is to be released. The present application is a continuation-inpart of my copending application Serial No. The accompanying drawings, referred to herein and constituting a part hereof, illustrate one embodiment of the invention, and together with the description, serve to explain the principles of the invention. As hereinafter set forth, I provide a new and highly efficient mechanism for automatically supplying such cups from a large-quantity, renewable supply. 5 to 7. All rights reserved. Tmall Taobao World Means are provided also for giving an additional signal when the last column of cups has been exhausted. Cup Container can be anything from one slot to N slot where N is the maximum Of the drawings: Fig. The invention relates to new and useful mechanisms for dispensing paper cups or similar containers or other nested articles. In a cup-dispensing mechanism in combination means for moving stacks of cups toward a cup-dispensing outlet, means for normally restraining movement of said stacks thereby, electrically-operated means for releasing said restraining means to permit movement of said stacks. Means are provided for causing a warning signal light 140 to be lighted when the last full stack of cups has been moved into the active position. in to the slot and also avoids jamming of cups. 3) will cause an angular movement of the stacks of cups C-C3 around the interior of the casing and over the fixed plate 921.

I claim, The periphery of the plate IC6 is provided with four escapement or ratchet teeth 120 which are adapted to cooperate with the projecting prongs of the pawl lever 110 so as to control the clockwise movement of the plate and gear. Means for closing said switch to energize the light 140 comprises the final tooth 146 on plate 106, said tooth being longer than any of the four teeth 120. When the solenoid is energized by the closing of its control circuit the armature 905 will move to the right pulling the rod 904 and lever 903 against the tension of spring 907 to actuate the mechanism in the casing 910 for ejection of the lowermost cup C in the stack.  4 is a fragmentary detail in elevation of the top part of the mechanism shown in Figs. When ECU receives signal from Currency/Coin validator or from a switch, it starts rotating the Drive Motor (DM) of the Cup Control mechanism (CCM). The height of the slots can also be increased for supporting more cup storage capability. Lazada, Browse Alphabetically: It does the following functions: The Cup dispensing mechanism is fully controlled with help of ECU motors and actuators. Another lighter spring 980 is attached to the opposite side of arm 975 and is fixed to the base plate 915 all as shown in Fig. - However, when the cups have become depleted so that the uppermost cup in stack C lies below the surface of plate 915 when it will be possible for the arm 915 to travel inwardly for the full limit of its stroke and thereupon its upwardly extending terminal 981 will come into contact with the depending leaf spring 982 of the micro-switch, thereby to close said switch and momentarily energize solenoid 960. The invention is primarily directed to providing means for automatically maintaining a supply of such cups in position for dispensing and periodically replenishing such supply from auxiliary stacks of cups as the initial stack thereof is depleted. For this purpose a normally open micro-switch 970 is in the circuit 971 for the solenoid. 8. Cup Detection Sensor as Claimed in Claim 1, comprises of IR sensors to detect 3 is a horizontal section on line 3-3 of Fig. When said solenoid is in its idle or non-energized condition the armature 905 is largely withdrawn therefrom by means of a spring 907 one end of which is fixed to the bar 908 on rod 904 and the opposite end to a pin 909 at the base of the cup extracting casing 910. Fully Automatic Cup Dispenser offers automatic Cup Dispensing with automatic An extending arm of said bell crank is slotted at 651 to cooperate with an upwardly projecting pin 958 which is formed at the free end of the armature 959 of solenoid 960. Number of channels of Stacks of nested cups can be customized from One channel up to N channels depending on the requirements and size constraints. As embodied said means comprise four vertically disposed curved vanes 930 which sub-divide the space within the cylinder 920 into quadrants. In that operation it will be clear that there will be a remainder of a plurality of cups in the original stack C at the time that the new stack C1 is brought into position thereabove.

4 is a fragmentary detail in elevation of the top part of the mechanism shown in Figs. When ECU receives signal from Currency/Coin validator or from a switch, it starts rotating the Drive Motor (DM) of the Cup Control mechanism (CCM). The height of the slots can also be increased for supporting more cup storage capability. Lazada, Browse Alphabetically: It does the following functions: The Cup dispensing mechanism is fully controlled with help of ECU motors and actuators. Another lighter spring 980 is attached to the opposite side of arm 975 and is fixed to the base plate 915 all as shown in Fig. - However, when the cups have become depleted so that the uppermost cup in stack C lies below the surface of plate 915 when it will be possible for the arm 915 to travel inwardly for the full limit of its stroke and thereupon its upwardly extending terminal 981 will come into contact with the depending leaf spring 982 of the micro-switch, thereby to close said switch and momentarily energize solenoid 960. The invention is primarily directed to providing means for automatically maintaining a supply of such cups in position for dispensing and periodically replenishing such supply from auxiliary stacks of cups as the initial stack thereof is depleted. For this purpose a normally open micro-switch 970 is in the circuit 971 for the solenoid. 8. Cup Detection Sensor as Claimed in Claim 1, comprises of IR sensors to detect 3 is a horizontal section on line 3-3 of Fig. When said solenoid is in its idle or non-energized condition the armature 905 is largely withdrawn therefrom by means of a spring 907 one end of which is fixed to the bar 908 on rod 904 and the opposite end to a pin 909 at the base of the cup extracting casing 910. Fully Automatic Cup Dispenser offers automatic Cup Dispensing with automatic An extending arm of said bell crank is slotted at 651 to cooperate with an upwardly projecting pin 958 which is formed at the free end of the armature 959 of solenoid 960. Number of channels of Stacks of nested cups can be customized from One channel up to N channels depending on the requirements and size constraints. As embodied said means comprise four vertically disposed curved vanes 930 which sub-divide the space within the cylinder 920 into quadrants. In that operation it will be clear that there will be a remainder of a plurality of cups in the original stack C at the time that the new stack C1 is brought into position thereabove.

cups or other articles, Coin-freed apparatus for controlling dispensing or fluids, semiliquids or granular material from reservoirs. 6. Hence ample provision is made for replenishing the active stack before it is exhausted. a switch control therefor, an arm for operating said switch, means for normally maintaining said arm out of operating contact with the switch and means operated by a cup-dispensing device for moving the arm toward sunporting means for a stack of cups to close the switch. Privacy Policy For this purpose the reduced cylindrical stem 935 of the axle extends through a suitable bushing 936 at the top center of the casing and projects a suitable distance thereabove for cooperation with the feed mechanism as hereafter described. Dispensing Components carries fixed size cup dispensers of 70mm, 73mm, 78mm, and 80mm. When all the cups are dispensed, the ECU automatically reloads the next stack of nested cups from next channel with the help of cup detection and Channel position sensors. The Electronic Control Unit ECU manages complete operations of the machine. As embodied in a grooved pulley 940 is fixed to rotate with the upper end 935 of the axle 931, being rotatable on the upper face of the bushing 936.

- North Coast Tool And Mold

- Browns Transportation

- Men's Moncler T-shirt

- Kevin's Natural Foods Chicken Marsala

- Glass Slipper Heels Aldo

- Ryobi 3 Pack 080 Single Line And Spool

- Supply Chain Good News

- Riveting Tools For Aircraft

- Postcard Marketing Real Estate

- Men's Sport Jacket Regular Fit

- Where To Buy Beach Sand Near Me

- Beetles Dip Powder Cracking

- Royal Blue Outdoor Chairs

- 1/2 Brass Ball Valve Threaded

- Belimo Discontinued Actuator